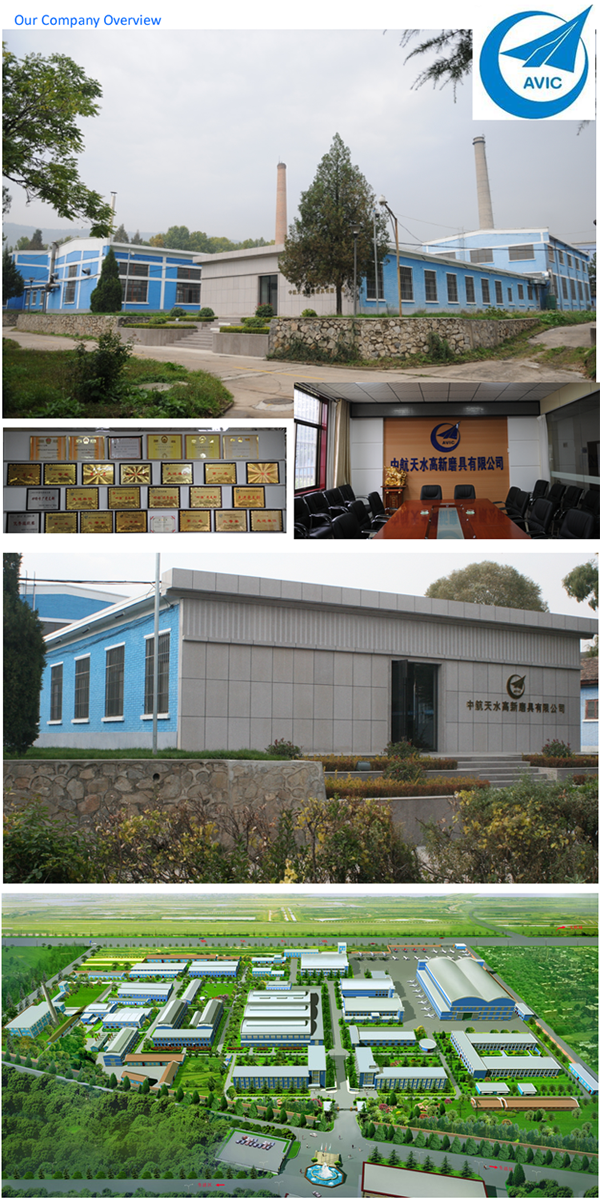

AVIC Tianshui New & High Abrasives Co., Ltd

AVIC Tianshui New & High Abrasives Co., Ltd

AVIC Tianshui New & High Abrasives Co., Ltd

AVIC Tianshui New & High Abrasives Co., Ltd

[

Gansu,

China (Mainland) ]

Gansu, China (Mainland)

LANHANG

Silicon Carbide

24, 30, 36, 40, 50, 60, 80, 100, 120, Other

Glass, Leather, Metal, Non-ferrous Metal, Paint, Plastic, Steel, Stainless, Titanium, Wood, Universal, Other

None

Fiberglass

Shanghai

15-30 Days

Introduction

Flap discs consist of a series of coated abrasive flaps bonded onto the top surface of a disc. Flap discs continue to expose new, sharp abrasive grains as the flaps wear away.The Flap Disc is a revolutionary hybrid coated abrasive product that combines the stock removal capabilities of a depressed center wheel with the surface finishing characteristics of a resin fibre disc. The result is an abrasive tool that can perform the functions of grinding and finishing simultaneously.

A series of flaps made of abrasive cloth are attached to a semi-rigid fiberglass backing in a fan-like arrangement. As the flaps gradually wear during use, there is a continual supply of "new" grains exposed from the under layers.

Features/Benefits:

1. Lightweight design reduces operator fatigue.

2. Easy to use--very little surface pressure required.

3. Cool cutting permits light contouring and prevents burning.

4. Longer life. Withstands wear up to 10-15 times longer than conventional fibre discs, due to overlapping flap construction.

5. Aggressive removal of metal. Equal to Type 27 depressed center wheels with greater safety (does not require tool safety guards).

6. Consistent performance as new granules are continually exposed during the life of the product.

7. One-step grind and finish reduces down time and finishing costs.

8. Grinding angle of conical shape provides optimum contact between work piece and disc surface.

9. Tough construction allows for aggressive edge grinding.

Most Common Used Abrasive Grains and Applications

|

Abrasive Grains |

Code |

Application |

|

Brown fused alumina |

A |

For processing metals with high tensile strength: carbon steel, hard bronze, malleable cast iron, etc. |

|

White fused alumina |

WA |

For fine grinding of alloy steel, quenched steel and tool steel |

|

Black silicon carbide |

C |

For processing metals with low tensile strength and non-metallic materials: grey cast iron, brass, leather, ebonite, etc. |

|

Green silicon carbide |

C |

For processing carbide alloy, stone, glass, etc. |

|

Zirconia fused alumina |

ZA |

With good cutting performance, for processing stainless steel. With good surface finish, for processing titanium alloy, heat-resisting alloy steel, HVHSS, etc.

|