AVIC Tianshui New & High Abrasives Co., Ltd

AVIC Tianshui New & High Abrasives Co., Ltd

AVIC Tianshui New & High Abrasives Co., Ltd

AVIC Tianshui New & High Abrasives Co., Ltd

[

Gansu,

China (Mainland) ]

Gansu, China (Mainland)

LANHANG

Aluminum Oxide

115mm (4-1/2'')

Other

Specialty

Medium

Dry

Tianjin/Qingdao/Shanghai

15-30 days

L/C, T/T

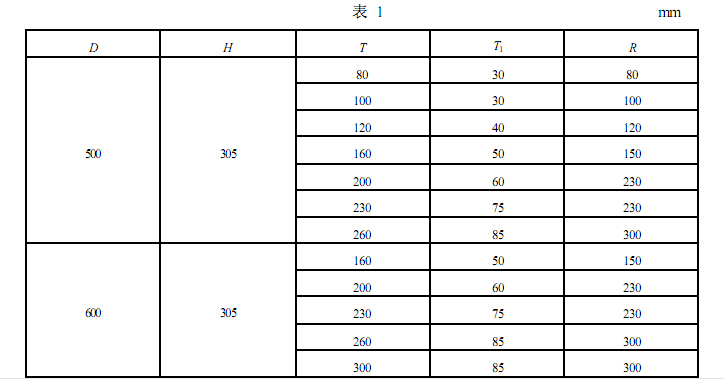

1.Specification

Max Operation Linear velocity: 35 M/S

2. Advantage

1) Products have the characteristic of long lifetime and good balance.

2) All products will be supplied according to customers’ different requirements.

3. Application

They are used to grind spherical surface bearing.

4. Other

1. Package: As per client's request.

2. Delivery: 15-30days

3. Just contact me for the latest information without hesitation.

5. The Operation of Abrasive Products

Dos

1. Before start the machine,always ensure various protective devices of machine tools and reset switch of various actions are adjusted in position.

2. Using protective cover, always ensure that it covers at least half the diameter of the grinding wheel.

3. Before starting to use the new installation of grinding wheel which has been dressed, always ensure grinding wheel idles for one minute at operating speed with the guard of protective cover.

4. When grinding, always wear safety goggles or other similar safety supplies.

5. Dressing or using grinding wheel, always touch lightly.

6. When necessary, always dress grinding wheel.

7. Before grinding wheel stop running, always close cooling fluid to avoid grinding wheel unbalance.

DON’Ts:

1. Use grinding wheel at an speed which exceeds the highest limit speed.

2. Start machine tool without protective cover.

3. Stand directly in the face of machine tools after starting machine.

4. Force workpieces into grinding wheel which lead to grinding pressure and feed are excessive.

5. Force grinding which lead to machine motor slow down obviously or workpieces burning hot.

6. Put stationary grinding wheel in liquid.

7. Impose external forces on grinding wheel to make it stop running.

8. Continue to use grinding wheel without dress which surface has glazed.

9. Make grinding wheel used in other operations which are incompatible with their design.

10. Operator works without safety education and related certificates.

We sincerely wish to enter into long-lasting cooperation relationship with every new and old customer.