ZHEGNZHOU BOSDI ABRASIVES CO.,LTD

ZHEGNZHOU BOSDI ABRASIVES CO.,LTD

ZHEGNZHOU BOSDI ABRASIVES CO.,LTD

ZHEGNZHOU BOSDI ABRASIVES CO.,LTD

[

Henan,

China (Mainland) ]

Non Ferrous Products Grinding wheel with Powerful Backing Support

Grooving Grinding Wheel for Tempered Glass Non-ferrous Products

100*16mm flexible flap disc radial flap disc plastic backing

A/C 24#-46# depressed centre fiber net polishing and cutting disc

cup-shaped rail track grinding wheel with four threaded hole

WA60 105*1.5*16mm doube net cutting wheel for stainless steel

T41 Abrasive super thin straight cutting wheels, cutting disc

100*6*16 mm depressed center fiberglass reinforce grinding wheels

Zirconia-Alumina depressed center cutting and gringding wheels

fiberglass reinforce double net cutting wheel, cutting disc,

T41 fiber reinforce green cutt-off wheel for cutting and grooving

T42 black flexible grinding and cutting disc, gringding wheel

Red 4'' two nets thin cutting wheel, cutting disc, cut-off wheel

resin black cut-off wheel for metal, stainless steel, alloys.

metal cutting wheel with resin bonded, cutting disc, cut-off wheel

Henan, China (Mainland)

BOSDI

GC1251020t41

Silicon Carbide

125mm (5'')

Cylinder

Surface/Creep-feed

Resin

Dense

Dry/Wet

125*10*20mm

Pieces

10

architectureal glass coating deletion wheel film deletion wheel

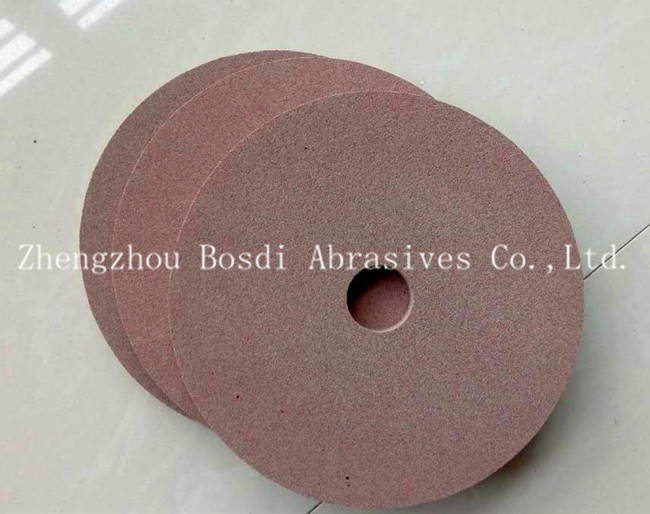

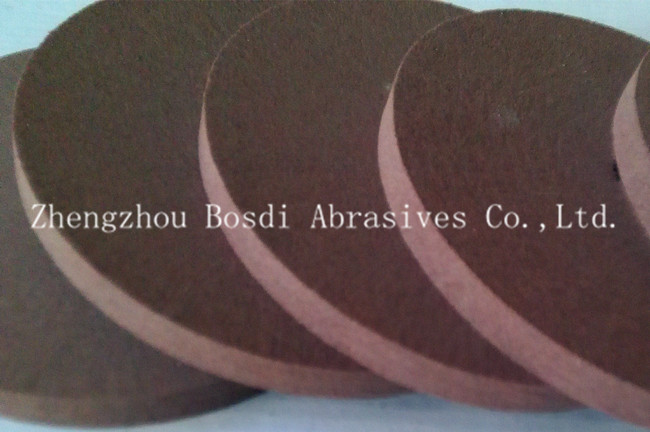

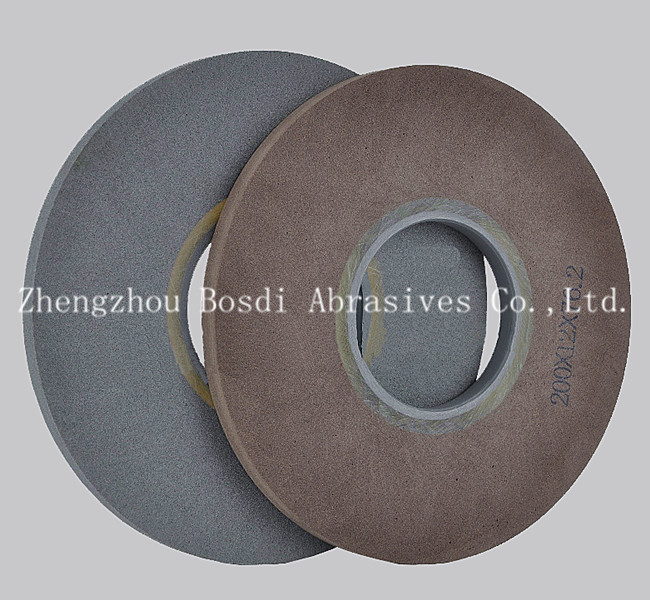

Glass Edge Coating/Film Removal Wheel:

Why Edge Delete

Due to energy saving and environmental friendly, low-e coating glass becomes more important in architectural and building industries. Low-e coating is a very delicate thin film depositing on glass surface. Therefore, low-e glass is always insulated with another piece of glass. Low-e coating always faces in the inner side of double glazing. The space is either ordinary dry air or filled up with inert gas. The dry air or inert gas would not corrode the low-e coating. This protects low-e coating from corrosion.

The space between two pieces of glass is always separated by spacer bar. Spacer bar could be aluminum, steel, stainless steel, reinforced plastic or rubber. Due to its excellent moisture proof, butyl is chosen to be the adhesive to seal between spacer bar and glass. However, the adhesion between butyl and low-e coating does not perform well. Consequently, it is always required to remove the low-e coating around the edges of the glass. This process is known as low-e edge deletion. After low-e edges are deleted, glass edges are exposed. Butyl gets in direct contact with glass. This allows the adhesion in best performance.

architectureal glass coating deletion wheel film deletion wheel

Features:

1. High fineness and excellent polishing;

2. Sharpness and good self-sharpening;

3. Strong intensity and safety in use.

Applications:

1. Particular suitable for removing the edge film of vacuum glass;

2. Be suit for polishing glass or the edge of organic glass;

3. Be widely used in the field of glass.

Specifications:

|

Commodity Item No. |

Dimension |

Speed (m/s) |

Packaging(PCS/CTN) |

|

|

mm |

inch |

|||

|

GC1251020T41 |

125x10x20 |

5" x 2/5"x4/5” |

35 |

200 |

|

GC1501020T41 |

150x10x20 |

6" x 2/5"x4/5” |

35 |

200 |

|

GC1502076T41 |

150x20x76 |

6" x 4/5"x3” |

35 |

200 |

|

GC2001076T41 |

200x10x76 |

8" x 2/5”x3" |

35 |

100 |

|

GC2001276T41 |

200x12x76 |

8" x 2/5”x3" |

35 |

100 |

|

GC2001376T41 |

200x13x76 |

8" x 2/5”x3" |

35 |

100 |

architectureal glass coating deletion wheel film deletion wheel

pictures: