ZHEGNZHOU BOSDI ABRASIVES CO.,LTD

ZHEGNZHOU BOSDI ABRASIVES CO.,LTD

ZHEGNZHOU BOSDI ABRASIVES CO.,LTD

ZHEGNZHOU BOSDI ABRASIVES CO.,LTD

[

Henan,

China (Mainland) ]

Non Ferrous Products Grinding wheel with Powerful Backing Support

Grooving Grinding Wheel for Tempered Glass Non-ferrous Products

100*16mm flexible flap disc radial flap disc plastic backing

A/C 24#-46# depressed centre fiber net polishing and cutting disc

cup-shaped rail track grinding wheel with four threaded hole

WA60 105*1.5*16mm doube net cutting wheel for stainless steel

T41 Abrasive super thin straight cutting wheels, cutting disc

100*6*16 mm depressed center fiberglass reinforce grinding wheels

Zirconia-Alumina depressed center cutting and gringding wheels

fiberglass reinforce double net cutting wheel, cutting disc,

T41 fiber reinforce green cutt-off wheel for cutting and grooving

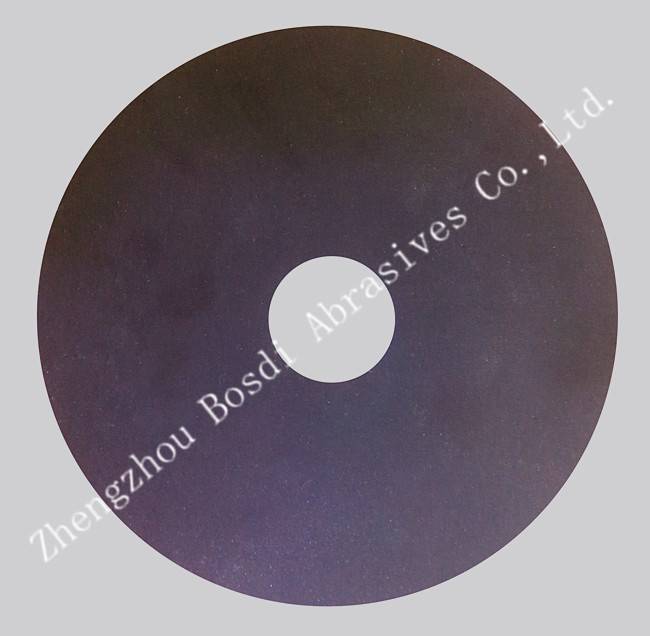

T42 black flexible grinding and cutting disc, gringding wheel

Red 4'' two nets thin cutting wheel, cutting disc, cut-off wheel

resin black cut-off wheel for metal, stainless steel, alloys.

metal cutting wheel with resin bonded, cutting disc, cut-off wheel

Henan, China (Mainland)

BOSDI

White Aluminum Oxide

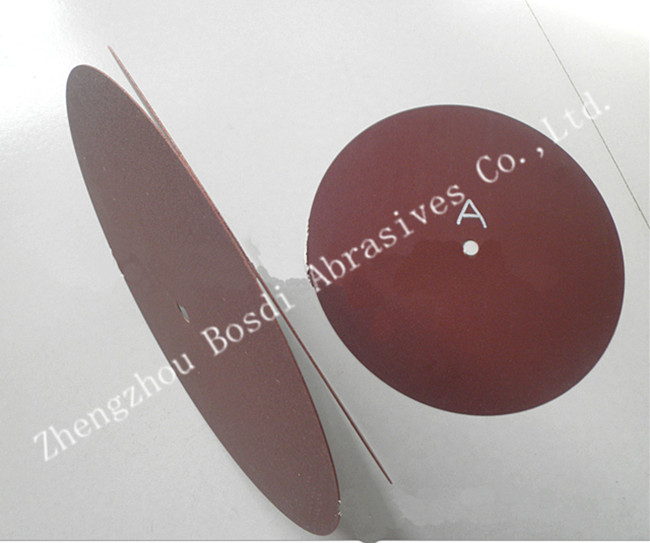

75/80mm (3''), 115mm (4-1/2''), 125mm (5''), 150/155mm (6''), 175/180mm (7''), 225/230mm (9''), 250/254mm (10'')

Other

Aluminum, Cast Iron, Cast Steel, Gray Casting, Glass, Nickel Alloy, Plastics, Stainless

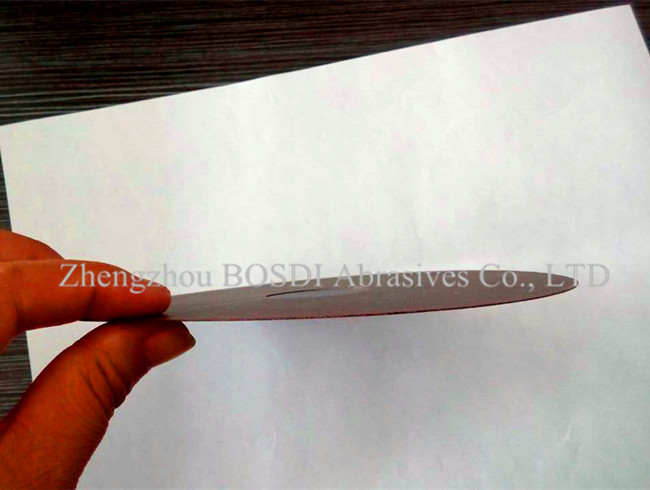

Thin(<2mm)

WA, C, SC,

#240, W28, W14 etc

180*0.3/0.5/0.7*25.4/32

Pieces

200

Shanghai

20 work day after receiving 30% deposite

Yes

500000000 / Year

T/T

Rubber Bonded ultra-thin cutting wheel,

The thinnest one is 0.1mm,

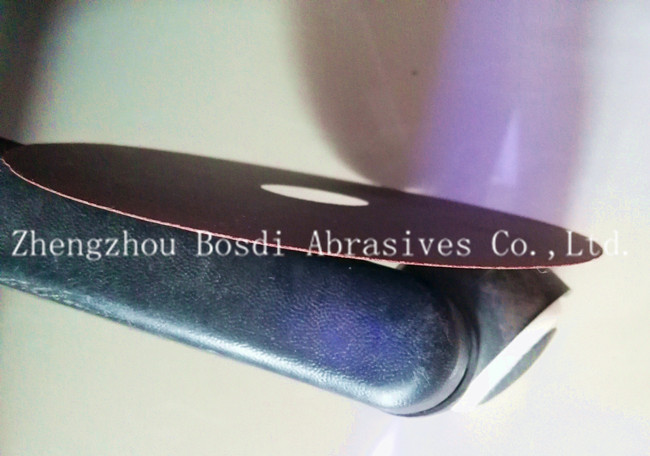

1. Cutting or grooving optical glass, quartz products, mono-crystal, multi-crystal SCR component, carbide alloy, mineral, hi-temperature ceramics, refractory body and other nonferrous metal material;

2. Grooving or cutting off skd-11 steels, carbon steel, high-speed steel, stainless steel, nonferrous metal, cast iron etc;

3. Cutting or grooving glass, ceramics, plastic, quartz, crystal, coral, jewelry, electric resistance, Bakelite, PCB board, shell non-metallic material.

Features:

1. Ultra thin, no net, high precision cutting, not easy to be broken;

2. Excellent intensity and flexibility, highly in sharpness and durability;

3. Can cutting in angle, and narrow blade and saving working object material;

4. Mostly apply for stationary cutting machine.

Applications:

1. Be used for cutting brake lines, cables and flexible shafts and bearing etc;

2. Grooving iron plate, small diameter stainless steel pipe and alloy bars, precision mold and machine tool accessory;

3. Cutting and grooving special steel, alloy and precious metal.

Order proposals:

According different processing requirements, providing you the best cutting wheel

1. Dimension ( outer diameter, inner diameter, thick, abrasives working layer thick)

2. Specifications (abrasives, grit, bonded etc.)

3. Applications (work piece name, cutting dimension, cutting material, grooving or cutting off )

4. Operation conditions (machine tools, speed, feeding speed, cutting depth, wet or dry)

5. Cutting requirements (cutting precision, surface fineness and integrity, wheel’s lifetime )

Any sizes and thickness could be order