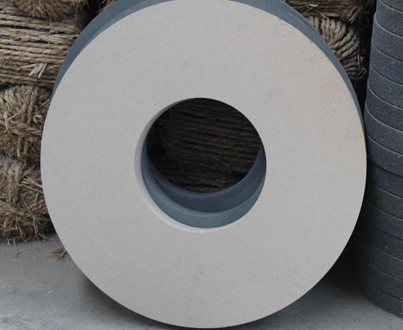

This article introduces how to select suitable abrasive grains, common grinding wheels and their applications. Please click for more details.

Abrasive grains that abrasives manufacturers most often produce are generally brown fused alumina and white fused alumina, followed by black silicon carbide and green silicon carbide, and the rest that are commonly used include pink fused alumina, monocrystalline alumina, microcrystalline alumina, zirconia fused alumina, etc. Among them, brown fused alumina has high hardness and toughness, suitable for grinding high tensile strength metals, such as carbon steel, alloy steel, malleable cast iron, hard bronze, etc. This kind of abrasive has great grinding performance and wide adaptability, usually used for coarse grinding removing larger allowance. The price is cheap and it can be widely used.

In general, abrasives with high toughness are used for materials with high tensile strength; If materials have low hardness and large elongation, please select brittle abrasives; When grinding materials with high hardness, please select some abrasives with higher hardness; Please select this kind of abrasives that will not have chemical reactions with machined materials.

White fused alumina grinding wheel: The hardness of white fused alumina is slightly higher than that of brown fused alumina, but the toughness is lower than brown fused alumina. When in the process of grinding, abrasive grains are easily broken. A a result, its grinding heat is small, suitable for manufacturing fine grinding hardened steel, high carbon steel, high speed steel and some grinding wheels that are used for grinding thin-walled parts. Its cost is higher than brown fused alumina.

Black silicon carbide grinding wheel: black silicon carbide is sharp and crisp, but its hardness is higher than white fused alumina. It is suitable for grinding materials with lower mechanical strength, such as cast iron, brass, aluminum, refractory, etc.

Green silicon carbide grinding wheel: Green silicon carbide has higher hardness and brittleness than black silicon carbide, which is sharp and has good thermal conductivity, suitable for grinding hard alloy, optical glass, ceramics and other hard brittle materials.

Pink fused alumina grinding wheel: It is suitable for grinding tools, measuring tools, instruments and other artifacts that have high quality requirements for surface processing.

Monocrystalline alumina grinding wheel: It is suitable for grinding stainless steel, high vanadium high speed steel and other materials with high toughness, high hardness and easy to burn and deform.

Microcrystalline alumina grinding wheel: It is suitable for grinding stainless steel, bearing steel, special nodular cast iron, etc., and also used for forming grinding, mirror grinding and so on.

Zirconia alumina grinding wheel: It is suitable for grinding stainless steel, titanium alloy, heat-resistant alloy, and especially suitable for heavy duty grinding.