Different ceramic alumina abrasive from different manufacturer has slightly different performance, mainly focus on below aspect

Different ceramic alumina abrasive from different manufacturer has slightly different performance, mainly focus on below aspect:

|

Physical Parameter |

Range |

Test method/equipment |

|

True density,g/mm3 |

3.85-3.95 |

Helium density |

|

Hardness, HV |

1600-2200 |

Micro Viker |

|

Crystalline size,nm |

50-500 |

Scanning Electron Microscope |

|

Ball mill toughness,% |

35-85 |

Ball mill and particle distribution |

These parameters will directly affect the grinding performance of Ceramic Alumina Abrasive. Please refer to below table:

|

Item |

Mechanism |

Effect to the grinding process |

|

True density |

Low true density means high porosity within abrasive grains. |

Less than 3.85g/mm3 for ceramic alumina abrasive means grains are easy to be broken and lower durability due to porosity |

|

Hardness |

Means the ability of grains to resist deformation at the force |

More than twice as workpiece hardness is enough |

|

Crystalline size |

The size of the tiny cell to build abrasive grain |

Bigger crystalline size, more strength of grain, more durability and less sharpness. Smaller crystalline size, more sharpness, less durability and less strength of grain. |

|

Ball mill toughness |

Toughness means the ability of grains to resist the impact force |

45-70% is a reasonable range, less than this means easy to be fractured. Bigger than this means too strong and less sharpness. |

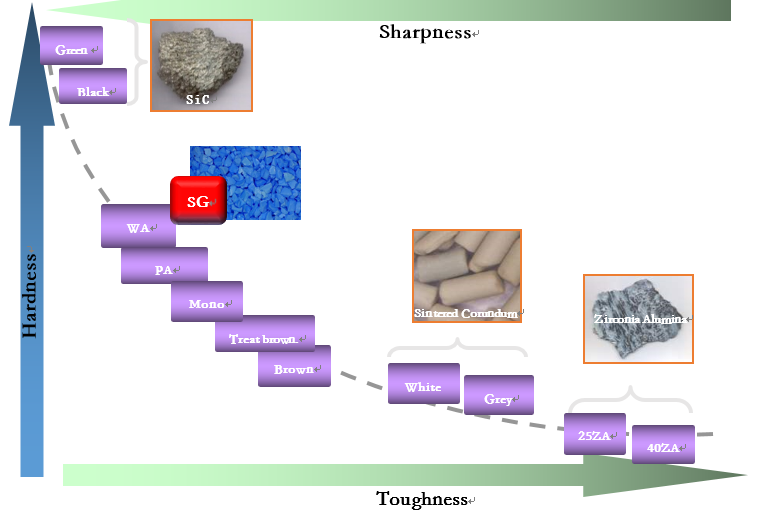

For abrasive grains, 3 key characters are hardness, toughness, and sharpness. Below is a map of different materials.

When design a grinding tool, it’s needed to consider the character of different abrasive grains to achieve better performance.

From: DOMILL Abrasive