Ceramic Alumina Abrasive, generally called “SG” is a newly developed alumina abrasive. Different from fused alumina, it is made from chemical and sintering process. Now several commercial brands have gone into the abrasive market

Ceramic Alumina Abrasive, generally called “SG” is a newly developed alumina abrasive. Different from fused alumina, it is made from the chemical and sintering process. Now several commercial brands have gone into the abrasive market, such as XTL, HTB, Cubitron, CA, BCA, SG-S, TG, etc.

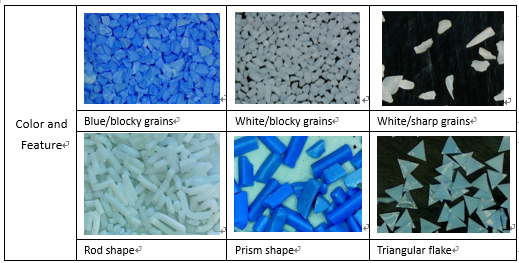

It mainly shows a white or blue color and has a sharp or blocky natural shape. Also grains with different precise shapes such as rod/prism/triangular have been developed for different applications.

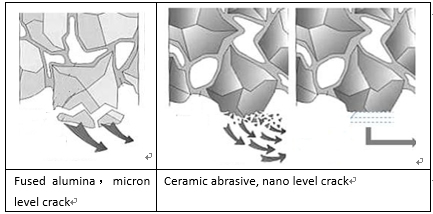

Ceramic alumina abrasive in the grinding process, the fracture mechanism is different from fused alumina. The core theory is continuous to create a new nano level sharp blade for cutting, then the ceramic alumina abrasive can have more efficiency and more durability.

For the nano level crack feature, the ceramic abrasive is fit for hard material grinding, such as aerospace alloy, hard tool steel, and hard forged steel, etc. And ceramic alumina abrasive can be made to different kinds of grinding tools, such as a bonded wheel, depress wheel, coated abrasive, etc. Usually it is mixed with other grains for better cost and different applications.

From: DOMILL Abrasive