In recent years, China superhard abrasives industry has seen a rapid growth. However, gap still exists between China and foreign countries in Europe and America. Except for technology and raw materials.

In recent years, China superhard abrasives industry has seen a rapid growth. However, gap still exists between China and foreign countries in Europe and America. Except for technology and raw materials, China is capable of yielding better products under current technology conditions.

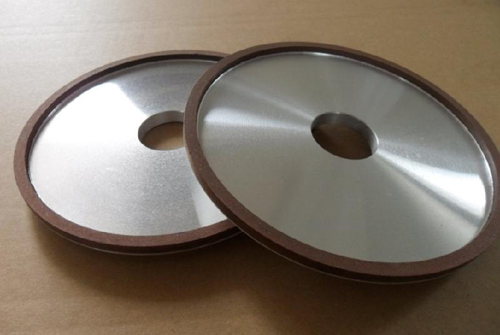

Take diamond resin grinding wheel for example, at present foreign manufacturers usually adopt surface plating Ti, Ni as abrasive grains for grinding wheel whose service life is several times longer than that of ordinary grinding wheel. As we all know that diamond abrasive grains only play 10% in grinding effect, most diamond either turns too hot or influenced by external force, which conditioned resin grinding wheel working efficiency and service life.

After diamond surface metallization, its comprehensive properties are improved accordingly. Firstly, obvious spinous structure in diamond surface, namely, diamond surface roughening, has greatly improved bonding agent holding force. What's more, diamond compressive strength can improve 40% to 55% or so after surface metallization, which greatly protect diamond from broken or wear. Meanwhile, Ti, Ni have good thermal conductivity that help to prevent diamond abrasive grains graphitization in high temperature.

Of course, diamond surface metallization abrasive grains have disadvantages. It is known to all that resin-bonded grinding wheel is sharper in that during working process, diamond abrasive grains keep being broken and dropping. While metal plating diamond can hardly achieve the effect since it is coated with Ti or Ni. The producing cost is increased and China product price and profit are much lower tham those of imported goods.

In general, although diamond surface metallization has considerate advantages compared to ordinary abrasive grains, simply imitating foreign usage is not practical. In fact, Chinese abrasives manufacturers can adopt another approach by adding over 20% Ti and Ni diamond in bonding agent, thus grinding wheel service life is greatly enhanced without reducing sharpness. Proper plating abrasive grains in bonding agent play a protective role.

Experiments prove that resin grinding wheel produced in the above approach has service life 1 to 1.2 times longer than ordinary diamond abrasive grains. Of course, adding proportion can be still higher ignorant of cost, but in processing, even mixing is quite important.