The abrasive industry has been an indispensable part in various application fields, such as the ferrous metallurgy industry, the auto parts industry, the bearing and gear processing industry, the tool processing industry, etc.

The abrasive industry has been an indispensable part in various application fields, such as the ferrous metallurgy industry, the auto parts industry, the bearing and gear processing industry, the tool processing industry, the aerospace industry, the steam turbine manufacturing industry, the construction industry, the mold processing industry, the woodworking industry, the metal processing and casting industry, the general manufacturing industry, the electric semiconductor industry, and the hardware industry, just to name a few. iAbrasive will publish a series of articles concerning the major application fields of the abrasive industry. Let's begin with the first application field--the ferrous metallurgy industry.

The Ferrous Metallurgy Industry

Ranging from preliminary working of metal to finished products manufacturing, the abrasive industry has played an important role. To be specific, the major application covers steel slab surface finishing; mill roll surface grinding; wire rod, bar, and tubular products cutting; bar surface grinding and cleaning; and coiled material sheet metal, bar, and tubular products surface grinding and polishing.

High-performance abrasive grinding wheels have been successfully used in all kinds of rolling mill grinding to guarantee that the rolling mill's surface's has high smoothness, and an overall evenly distributed effect, and is without defects. The abrasive cutting discs are used in steel cutting. Since grinding and polishing processes have a direct impact on the quality of finished steel products, the coated abrasives can be applied in coiled materials, steel belts, sheet metal, bar, and tubular products surface grinding and polishing. For instance, an abrasive belt can achieve a stable and consistent fine polishing effect.

The Auto Parts Industry

The second application field is the auto parts industry. Abrasives grinding, polishing, and buffing can help auto parts manufacturers improve production efficiency, and product quality, and reduce production costs. The abrasives products are widely used in automobile engines, speed change and steering systems, auxiliary body grinding, car polish, paint polishing, auto glass preconditioning application, etc.

The engine is an important part in the auto manufacturing industry. With the advancement of technology, it has to meet the requirements of low energy consumption, low noise, and reduced waste air pollution, all of which are closely related to the processing quality and precision of auto parts. Diamond grinding wheels, diamond drill bits, and diamond abrasive belts are applied in auto glass round edge and chamfer edge processing.

Bearing & Gear Processing

With the rapid development of modern manufacturing industries, such as the auto industry and the machine tool industry, the market has an increasing demand for high-performance transmissions. The demanding requirements call for the ultra-high grinding precision. Bearing processing has the largest demand for abrasives. Ceramic bonded grinding wheels are widely used in bearing raceway, inside and outside circles, and roller processing. It has a good inflexibility and durability. The features of resin-bonded grinding wheels are large removal rate, good thermal diffusivity, and a high degree of finish. So they are used mainly in the two end faces of the bearings. Grinding heads are used in the bearings' bore diameter and the inner ditch. Honing sticks are applied in product super precision processing, while diamond and CBN products are used to achieve high precision of the bearing's sizes and consistent finishing results.

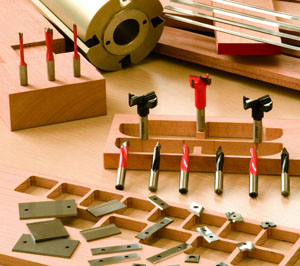

The Tool Processing Industry

With the fast development of metal cutting machines, the manufacturing of the supporting cutting tools has seen a daily rise. Drill bits, cutters and all the other tools have an intimate relationship with the grinding wheel's precision grinding. For example, milling cutters, turning tools, and pulling knives all require the grinding wheel to form their shapes. Among the manufacturing cost of the tools, except for labor costs and equipment costs, grinding wheels accounts for an important part of the total cost. So it is very important to decide whose grinding wheels to buy. iAbarsive recommends for that you use an experienced grinding wheel manufacturer in China--Zhengzhou Bosdi Abrasives Co., Ltd., whose abrasive products are positioned in the high-end market and that is well-known in China for its good product quality and longer service life of the grinding wheels.

The Aerospace Industry

You will find that the abrasive industry is used in every corner of the aerospace industry from rough machining to precision machining. For instance, bonded abrasives and coated abrasives made of ceramic aluminum oxide abrasive grains can be used in the stainless steel and titanium alloys of airplane manufacturing. Auto parts in the engines, screw propeller, and landing gears adopt mostly super alloy, such as turbine blades. In each part of the manufacturing process, the abrasive cutting discs, abrasive belts, ceramic bonded grinding wheels, and electroplated CBN grinding wheels have played their part. During the plane part and paint, abrasive discs, sanding paper, and other non-woven polishing products are employed to reduce the defect. The polishing abrasive belts are used to remove the surface injuries.

The Catalyst for the Construction Industry

Diamond saw blades, diamond drill bits, road cutting saw blades, grinding discs, cutting discs, and abrasive paper are used in the construction industry. To be specific, these abrasive products are used in infrastructure and municipal facility construction, such as road, bridge, tunnel, airports, house building, large construction markets, hardware building materials, etc.

Ranging from the most commonly seen residential decoration, to the abrasive paper in the wall's paint finishing and the resin cutting discs in door and window cutting, to the super diamond laser welding saw blades in bridge construction, and to the circular saw blades in concrete cutting and all kinds of stone materials, the abrasive products cover almost every aspect of the construction industry.

Meeting the Demand of the Woodworking Industry

No matter if it's a piece of wooden furniture, bamboo floors, or artificial board, the sand belt grinding is of vital importance to keep the workpieces' consistent quality, including smooth surface, evenly distributed thickness, etc. Before assembling the furniture, the components should be grinded by the sand belt to achieve better surface quality. Before furniture and musical instruments can be painted, the most commonly used tools are hand tools, such as a hand held sand machine, pneumatic sand disc machine, sand paper, and non-woven cloth. In the polishing workshop, the furniture with defects should be polished by non-woven grinding discs and a sanding sponge.

Related Article: The Abrasive Industry's Various Application Fields (PartⅡ)

Author: Liwei Chu

Copyright: iAbrasive.com--Abrasives & Diamond Tools Market