The abrasive industry has been an indispensable part in various application fields, such as the the general manufacturing industry, the electric semiconductor industry, and the hardware industry, just to name a few.

General Manufacturing Industry

The abrasive industry is helpful in solving issues with cutting, grinding, and polishing of all kinds of materials, such as railroad, vessel, container, power station, petrochemical, tube, and other machinery equipment fields. In the shipbuilding and container industries, the resin-bonded cutting discs and all kinds of coated abrasives can be used in the container and shipbuilding section's soldering seam cleaning as well as other metal surface treatment, such as stainless steel containers, steel structures, and petrochemical tubes.

For special occasions that require fast maintenance and cutting, high-performance ultra-thin cutting discs can meet the demand at an unbelievable cutting speed. With the improvement of locomotives' transport capacity and the speed per hour, the railway netting twine construction and maintenance has become more and more frequent. Special cutting discs and grinding wheels designed for railways have been widely used.

Semiconductor Industry

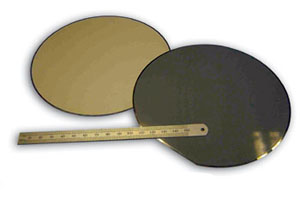

The abrasive industry provides supporting products for cutting, grinding, and dressing in the semiconductor industry. It is widely applied in silicon wafer preparation, the wafer process, and the package test. To be specific, it includes single crystalline silicon rod cutting and silicon wafer polishing pad dressing and grinding, etc. Besides that, the diamond products are also used in the HDD, the photovoltaic industry, and the TFT-LCD industry for providing technical supports.

The crystal bar is used to grind the grinding wheel's surface to make it smooth and reduce damage to the largest extent. Diamond circular cutting discs not only have a long service life but also have a superior quality. With the silicon wafers developing towards a large area, within the industry, many people choose to adopt wire-electrode cutting rather than internal cylindrical cutting. Edge grinding wheels are also used to remove the micro burrs.

Gain Cost Advantage for Metal Processing & Casting Industry

All casting processes requires the casting cleaning process, which is directly connected with the abrasives application. The major castings include auto parts, valves, pipe fittings, and heavy castings. The abrasive products can be applied to the coarse grinding, medium grinding, and fine grinding, such as resin cutting, grinding wheels, and high precision polishing.

Related Article: The Abrasive Industry's Various Application Fields (PartⅠ)

Author: Liwei Chu

Copyright: iAbrasive.com--Abrasives & Diamond Tools Market