Heavy-duty Grinding Wheel mainly uses resin bond whose grinding effect is the best among all kinds of abrasive products. It can easily be found on iAbrasive.com, a B2B abrasives webportal where specialized manufacturers are available.

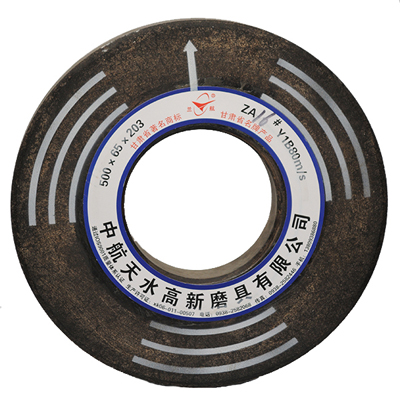

Heavy-duty grinding wheel mainly uses resin bond whose grinding effect is the best among all kinds of abrasive products. Heavy-duty grinding wheel is widely used in steel ingot, steel slab, and steel plate coping as well as surface cleaning of all kinds of castings. So heavy-duty grinding wheel is also called snagging wheel or grinding billet wheel. Products of such type can easily be found on iAbrasive.com, a B2B abrasives webportal where specialized manufacturers, such as AVIC Tianshui New & High Abrasives Co., Ltd., are available. The development of heavy-duty grinding wheel depends on the development of the steel industry and corresponding development of high production grinding machines.

Steel conditioning used to adopt ceramic bonded grinding wheels and resin bonded grinding wheels. The revolving strength of and impact strength of ceramic bonded grinding wheels are not as high as resin bonded grinding wheels, which has gradually replaced ceramic bonded grinding wheels.

Slab sharpening machine is often used by metallurgical companies to conduct surface working on stainless steel continuous casting billet. It is one of the important approaches to improve product quality by using a grinding wheel to grind the slab's surface and remove the oxide layer and surface defects. An important influencing factor is the metal removal rate and grinding ratio. The former is judged by the amount of removed metal in unit interval, while the latter refers to the ratio of the weight of removed metal and the consumptive weight. To reach a high metal removal rate, major ways are to improve the grinding wheel's linear velocity and increasing grinding force. However, the two ways will affect the grinding wheel's working life. So a better process is essential.

China's steel conditioning used to adopt suspension sharpening machine, the disadvantage of which is small grinding force, poor grinding quality, high labor intensity, and poor working conditions that are harmful for workers' health. The grinding process is so outdated that it can no long fit in with the modernized production of China's steel industry. Currently, China attaches great importance to steel conditioning. China has made numerous research into the project and brought in some grinding billet machines from abroad to meet the increasing demand for China's steel industry. Since 1960s, foreign countries have devoted major efforts to heavy-duty grinding. To tackle the machining problem and the grinding efficiency, the high speed heavy-duty grinding process was developed in 2000. The characteristics of the new process is that it has achieved mechanization and automation. The grinding efficiency has been improved substantially, the metal removal rate being 200kg to 800kg per hour. In terms of grinding wheel manufacturing, a higher requirement has been raised, that is, the abrasive used in the grinding wheel should be of rough particle size that can bear high grinding force, and the grinding wheel's working speed should reach more than 80m/s, and the hardness should reach superhard level to meet the demanding requirement of heavy-duty grinding technology. At present, foreign countries have produced and put into use high speed resin heavy-duty grinding wheel that can bear 1000kg grinding force and can work at 90m/s. According to statistics, resin grinding wheels used in the steel sector take up 85%, among which heavy-duty abrasive products account for 45%, medium-duty abrasive products occupy 30%, and low-duty abrasive products hold 10%. Besides that, heavy-duty abrasive products and medium-duty abrasive products have a close relationship with China's crude steel yield.

The technical features of heavy-duty snagging can be summarized as follow:

1. High grinding force, grinding wheel's speed, and metal removal rate, large grinding power, and high requirement for machine tool's stiffness and intensity.

2. Use heavy-duty grinding wheel that has high intensity, hardness, and rough particle sizes. Usually resin bond, brown fused alumina, microcrystalline fused alumina, sintered aluminum oxide, and zirconia alumina are used. The grinding wheel does not need dressing.

3. Adopt dry grinding method.

Author: Liwei Chu

Copyright: iAbrasive.com--Abrasives & Diamond Tools Market