This article introduces some measures to improve the grinding efficiency.

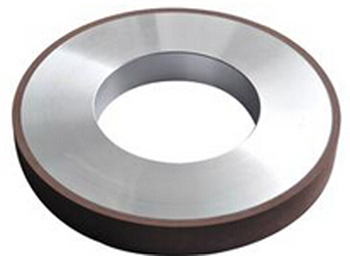

A, To choose abrasives with good cutting performance and grinding wheels with reasonable characteristics.

We should choose some abrasives with good machinability, such as diamonds and cubic boron nitride, green silicon carbide, alumina sand, microcrystalline alumina and chromium corundum abrasives, etc. In the case of meeting the workpiece surface roughness, we should try choosing coarse-grained grinding wheels. Resin bond grinding wheels with good self-sharpening and high strength can keep the keenness of grinding wheels. Choosing appropriate hardness of grinding wheels can help reduce the time of the dressing. And some grinding wheels with loose organization can not only increase the grinding depth and feed, but also prevent the burns and deformation of workpieces, especially when grinding heat-sensitive materials and artifacts.

B, To choose high strength grinding wheels for high speed grinding.

When the speed of grinding wheel is improved, the quantity of abrasive grains per unit time is greatly increased, and if the cutting thickness of each particle can be similar to ordinary grinding, the feeding will be greatly increased and the production efficiency can also be improved.The experiment proves that when the speed of grinding wheel is increased from 20m1/s to 90m/s, the metal removal rate can be increased 10 times; the durability of grinding wheel can be increased 100~1000 times; the normal grinding force can be reduced nearly 80%; the time for grinding unit volume of metals can be reduced 90%; the workpiece surface roughness Ra can be reduced by 50%.

C, Wide wheel grinding can be chosen for machine tools.

This kind of grinding can increase the surface area, and decrease the vertical stroke length of workbench. Or we can choose the plunge-cut grinding, whose efficiency is much higher than general grinding.

D, Heavy grinding

Heavy grinding is a high efficiency grinding method driven by high power to obtain high metal removal rate as the main goal. It includes large cutting depth plane, vertical surface grinding, etc. This kind of grinding can directly grind workblank to the finished product, whose metal removal rate can reach more than 180kg/h.

E, Abrasive belt grinding

Because the length and width of abrasive belt is much bigger than that of grinding wheel, it has high grinding efficiency, and large amount of metal removal. What’s more, it is not easy to produce the grinding defects such as burns.

F, Combined grinding wheel grinding, grinding wheels grinding, electrolytic grinding and electrolytic grinding wheel grinding also can exponentially improve grinding efficiency.