Natural diamond cutting tools are mainly used for the ultra-precision mirror processing of red copper, copper alloy and precious non-ferrous metals such as gold, silver, rhodium, as well as some special parts.

Natural diamond cutting tools are mainly used for the ultra-precision mirror processing of red copper, copper alloy and precious non-ferrous metals such as gold, silver, rhodium, as well as special parts, such as disk videocorder, optical flat mirror, polygonal mirror, secondary mirror, etc. But its crystals has the anisotropic characteristic, and the cutting tool is expensive.

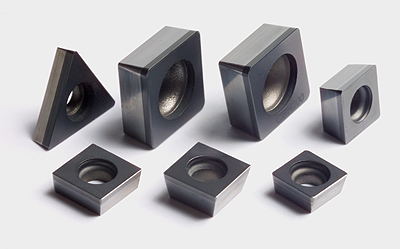

The performance of diamond compacts depends on the content of diamond crystals and cobalt. The service life of diamond cutting tool is about 10 ~ 500 times longer than cemented carbide (WC matrix ) cutting tools. They are mainly used for processing all kinds of non-ferrous metals such as aluminum, copper, magnesium and its alloy, hard alloy, fiber plasticized materials with strong wear resistance, metal matrix composites, wood and other non-metallic materials. Their cutting speed, feeding speed and cutting depth processing conditions depend on the workpiece material and hardness.

The performance and application of diamond compacts are very close to diamond cutting tools, mainly used in non-ferrous metals, cemented carbide, ceramics, non-metallic materials (plastic, hard rubber, carbon rod, wood, cement products, etc.) and composite materials, gradually substituting cemented carbide cutting tools. Because there are some residual binder and graphite in the diamond particles, the binder in coalescence state or vein shaped distribution will reduce wear resistance and life of diamond cutting tools.