Metal grinding materials are tailored solutions according to the shape of parts you need to process, and requirements of materials and precision. We will introduce the difference of this two kinds of abrasive papers.

Metal grinding materials are tailored solutions according to the shape of parts you need to process, and requirements of materials and precision. We will introduce the difference of this two kinds of abrasive papers.

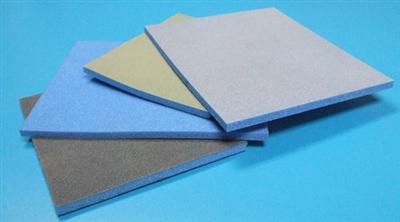

Metal grinding material sponge sandpaper is the main tools made up of abrasives bonded on flexible materials such as paper, cloth, used for grinding and polishing. Sponge sandpaper can be divided into paper backing tape and cloth backing tape: The paper backing tape is harder, which can grind out high surface finish. In the fine grinding and ultra fine grinding, the paper backing tape sponge sandpapers are widely used. Cloth backing tape has higher strength than paper backing tape, but the sensitivity for temperature and humidity is lower than paper backing tape, which will not lose stability by increasing of temperature and humidity. Cloth sponge sandpaper has longer durability than paper sponge sandpaper. In furniture production, the commonly used abrasives are alumina, silicon carbide, zirconium oxide aluminum, garnet, manual sandpaper, etc.

The characteristics of metal grinding material sponge sandpaper: coarse grinding, large plasticity and grinding areas; in order to avoid embedded chip and soft parts, coarse granularity should be chosen; Fine grinding and hard artifacts should choose fine grain. Metal grinding materials are bonded by the adhesive on the backing tape. Binder should have the strength, elasticity, heat resistance, water resistance, etc.

Waterproof abrasive paper is mainly used for the grinding and polishing of automobile, furniture, leather, household appliances and mechanical parts. Waterproof abrasive paper has small gaps between sands. The powder that is grinded out is also smaller, and will follow the water out l when using it with water. If you just use waterproof abrasive paper without water, the powder will stay in clearance of sands, which will make the sandpaper surface changing light and can not reach the ideal effect. The dry waterproof abrasive paper will not have the trouble, because it has large gaps between sands. The powder will fall down, so it don't need to be used together with water.

The features of waterproof abrasive paper: The grinding efficiency can be improved about30-50%, and it has long life and less grinding heat, high strength and tear resistance, and the resistance to plugging is also good. It also can prevent sandpaper to fade and affect the surface quality of the workpieces.