CBN is an extremely hard material and hence widely used as an abrasive, specifically in high-temperature applications. It is also widely used to coat a grinding wheel for fine grinding and lapping applications.

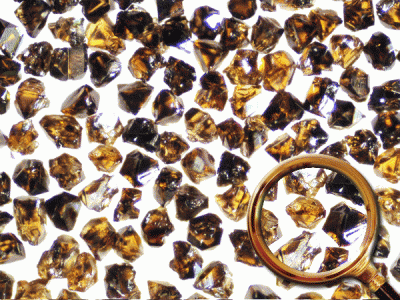

Cubic boron nitride (CBN) is a synthetically manufactured material, which is second to only diamond in hardness. One of its common synthesis processes is direct conversion of hexagonal boron nitride to CBN by treating at high pressure and temperature. CBN abrasives possess characteristics that exceed the values of conventional abrasives; for example, high strength and hardness, resistance to chemicals, heat, and abrasion; and ability to maintain the sharp cutting edges during use.

The products have been segmented into inserts, wheels, mesh and powder. The applications are segmented into raw abrasives, coatings, cutting & grinding, lapping & polishing, and others.

The product segment includes compounds of strontium such as inserts, wheels, mesh, and powder. Inserts are widely and predominantly used in cutting and grinding processes. Their shape, size, and content of CBN is determined by the processes in which they are expected to be employed. Powder is used as a raw material for manufacturing bonded abrasives, coated abrasives, polishes, cleaners, abrasive tools, grinding pastes, and other abrasive products. The application segment includes raw abrasives, coatings, cutting & grinding, lapping & polishing, and others.

CBN is an extremely hard material and hence widely used as an abrasive, specifically in high-temperature applications. It is also widely used to coat a grinding wheel for fine grinding and lapping applications. Since the cutting and grinding of hardened and carbide steel is difficult, CBN powder or mesh, in the form of a coated surface over a grinding or polishing wheel, is used to perform finishing processes such as polishing, grinding, and lapping.

CBN is a synthetic material produced by treating hexagonal boron nitride (hBN) at high pressure and temperature. This process is similar to the production of synthetic diamond from graphite. The pressure range required for the process is high; however, this range can lowered by addition of boron oxide during the reaction.

Sometimes, catalysts such as lithium, potassium, or magnesium and their nitrides and/or fluoronitrides are also required. To avoid growth of hexagonal phases or structures during explosive shock wave method or crystal growth in a temperature gradient method, boron trifluoride is added. These factors make the CBN manufacturing process expensive, which can act as a restraint to the market. Use of CBN has been increasingly recognized in 'tool and cutter' grinding applications as well as mass production grinding operations carried out in industries such as automotive, general engineering, and aerospace.

CBN tools are more advantageous in comparison to traditional abrasives, which acts as a driver for the CBN market. Key players profiled in the report include 3M, Saint-Gobain, Element Six, NanoDiamond Products, etc.