At present, cubic boron nitride is an effective tool material for hardfaced workpieces. It has high efficiency, high quality, high stability and other advantages, gaining people's trust in the field of hardfaced processing.

With the rapid development of modern technology and manufacturing, more and more manufacturing enterprises often use surfacing welding, spray welding, laser cladding and thermal spraying technology for melting hardfaced materials on the surface of workpieces, in order to improve product quality and service life, and also in order to gain higher hardness, wear resistance, corrosion resistance, impact toughness and other properties.

Surfacing welding, spray welding and other technologies are mainly used in the repair process in the beginning. But all industries have their own consumption parts that have high wear and tear, and some large parts are directly discarded after consumption, wasting resources, so this is the region of repair process later, which reduces the overall cost of production.

As the mature development of repair process technology gradually, the repair process will become more convenient and quicker. The service life of workpieces is not only recovered, and it does not affect the overall production schedule.

The hardness of workpieces is above HRC45 after repair, generally belonging to hardfaced workpieces that are difficult to process. And part of repair technologies have more strict requirements for the cutting tool performance.

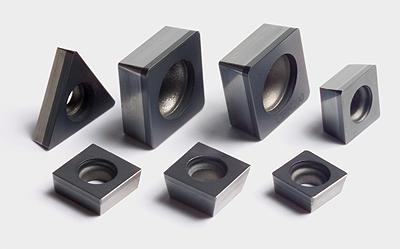

At present, the cutting tool materials on the market include cemented carbide cutting tools, ceramic knives and cubic boron nitride cutting tools. The performance of the above three kinds of cutting tools manufacturers must learn a lot. Cemented carbide cutting tools is the popular cutting tool, but is only suitable for processing some materials below HRC40; Although ceramic cutting tool is suitable for processing black metal material workpieces between HRC45-55, it is only suitable for finishing process because of the large brittleness. At present, cubic boron nitride is an effective tool material for hardfaced workpieces.

Cubic boron nitride cutting tool was used for machining in 1970, but because of the expensive cost, it didn't get good promotion at that time. But it has been widely used in recent ten years. With the increasing requirements for the product quality, the rising prices of raw materials, and the gradually weakened advantage of cheap labor, more and more manufacturers not only pay more attention to product quality, and at the same time, the cost and efficiency also become the issues of their concern.

Therefore, cubic boron nitride cutting tools gradually become popular tools accepted by people. It has high efficiency, high quality, high stability and other advantages, gaining people's trust in the field of hardfaced processing.