In 2012, there is a big event in coated abrasives industry that refers to the birth of full automatic flap disc machine. Then Dongguan Yuda has successfully held the promotion fair of full automatic flap disc machine.

In 2012, there is a big event in coated abrasives industry that refers to the birth of full automatic flap disc machine. Then Dongguan Yuda has successfully held the promotion fair of full automatic flap disc machine. Here, the detailed information about Yuda full automatic flap disc machine will be discussed in the article.

I. Device Structure

Machine head: the most important part of whole device. It can go up and down in the process of producing to make products get through.

Indexing system: it has the ability to transfer raw material to machine head and minimize the error.

Gluing system: it has the capacity of controlling the amount of glue to avoid drawing.

Gluing pump system: it is the high-tech part of the whole machine and makes temperature moderate and decrease the loss of glue. It can contain 280kg glue, which is enough for one-week working.

Vaccum system: it guarantees the clear working condition and makes it easy to clean up.

Loading system: the uploading and loading material can be done completely mechanically, which reduces labor intensity to avert deformation during the artificially move.

II. Technical Parameters

The machine has rotary multistation structure, the station converted stablely, and the positioning is accurate.

Thickness of substrate can be detected to adapt to a wide range of thickness tolerances.

Adopting new type of heating gumming system, the unit of glue is directly pressed into glue barrel and the amount of glue coming out one time can be set.

During placing pieces once the machine stops because abrasive cloth is not enough, after installing new sanding belt, the full automatic flap disc machine can continue to finish the subsequent placing pieces of the product.

When machine head replacing, there are digital display instructions. If changing product specification, it is able to transfer machine head to right place according to displayed parameters.

The machine head could change angle to suit the production of T29 flap disc.

It is allowed to display and adjust working parameters and working condition through touch screen online.

Products specification: Φ75 mm~Φ180 mm Type:T27/T29 (online adjustment)

Two-decks feeding system makes it possible to produce "double flaps" products.

Allowable tolerance in substrate thickness: ±1.0 mm (online regulate)

Glue barrel volume: 180L Amount of gumming glue: 6~30g (online adjustment)

The length of feed cloth: about 30mm (online regulate) The width of feed cloth: 38mm

Number of flaps: 24~150 (online adjustment)

Production speed: 6s/72 pieces

Operator: 1

Installed capacity: Motor : 5kw, Heating: 2kw

III. Compare with Similar Devices in Market

1. The thickness of substrate can be detected.

2. It can design gluing systems independently, and gumming glue quantitatively.

3. The transferring of machine head will be displayed by digital indicator.

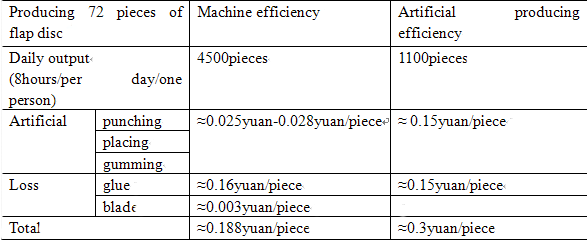

IV. Usability Analysis

V. After-sales Service

1. One year warranty, life-long maintenance (regular door-to-door maintainance)

2. Glue pump warranty 3 years, machine head 5 years warranty

3. Provide employee training

4. Provide technical parameters of products

5. Unconditional withdrawal machine if it cannot operate normally within three months

6. Free repair or upgrade in one year