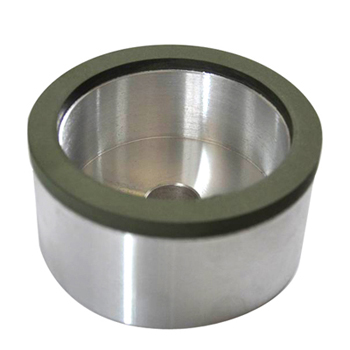

Diamond grinding wheels are necessary for glass industry. Diamond grinding wheels are synthetic diamond products whose major raw material is synthetic diamond that is processed under high temperature and high pressure.

Diamond grinding wheels are necessary for glass industry. Diamond grinding wheels are synthetic diamond products whose major raw material is synthetic diamond that is processed under high temperature and high pressure. They are widely used in hard alloy, non-ferrous metals and non-metals processing, such as diamond grinding plates, resin diamond grinding wheels, and polishing discs.

The utilization of diamond grinding wheels is closely related with choice of particle size, which affects directly the workpieces' surface, grinding efficiency, and abrasives products loss. In principle, choice of particle size should meet processing demand and use rough particles, which can improve grinding efficiency and decrease abrasives products loss. The grit size of diamond is usually from 30# to W1. 30# to 120# is for rough grinding, 120# to 240# is for medium grinding, 240# to W40 is for fine grinding, and W40 to W1 is for polishing.

Resin diamond grinding wheels mainly adopt phenolic resin and small amount of metal powder as bonding agent, while electroplated diamond grinding wheels use electrolytic deposition by depositing alnico on metal substarte's surface and fix diamond abrasive. The difference of the two types of diamond grinding wheels lie in three aspects:

1. In terms of processing efficiency, since electroplated grinding wheels adopt superior abrasive and only has a single layer, they have their own advantages in terms of heat radiation. So electroplated grinding wheels have a higher processing efficiency.

2. In terms of service life, electroplated diamond grinding wheels are inferior to resin diamond grinding wheels.

3. In terms of precision, electroplated grinding wheels have worse surface roughness of workpieces.