iAbrasive gives professional explanation about different types of fused alumina and their applications for your reference.

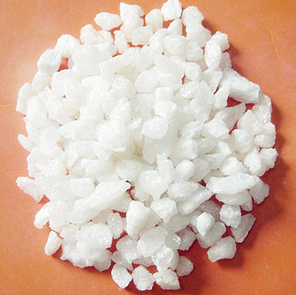

White Fused Alumina (WFA) is obtained from the fusion of high purity calcined alumina in electric arc furnaces. WFA is raw material characterized with high hardness, yet friable with high purity, chemical stability, a high melting point, and large crystal size.

White Fused Alumina is used in many applications including grinding and cut off wheels, refractories and ceramic shapes, coated abrasives, investment casting shells, laminates, coatings, blasting abrasives, lapping and polishing, and many, many more. See below for product information relating to your application.

Brown Fused Alumina (BFA) is produced by a reduction fusion of high quality bauxites in electric arc furnaces. It is both a hard and tough material with high strength, making it an excellent abrasive grain for applications such as grinding wheels, sandpaper, blasting media, metal preparation, lapping, polishing, and grinding. Its thermal properties make it an excellent raw material for refractory applications.

Pink and Ruby Fused Alumina is produced by adding chromium oxide to high purity aluminum oxide during the fusion process. The amount of chromium oxide added affects the color of the final product, as well as the toughness of the grain. With increased additions of chromium oxide, the toughness of the grain increases.

RU and RUHC are used in vitrified grinding wheels, coated abrasives, blasting abrasives and other applications.

For more information about abrasives, please visit: http://www.iabrasive.com/.