How to save abrasive in the design of sandblasters is an important issue to be tackled for sandblaster factories. There are six ways to save abrasive in sandblasters, they are: segregator, ash separator, recovery device, spray gun, sandpipe, and pressure.

Many abrasives manufacturers have been concerned about the abrasive loss in sandblasters. Abrasive is a consumable in sand blasters. Its considerable cost is like the gasoline in a car. How to save abrasive in the design of sandblasters is an important issue to be tackled for sandblaster factories. There are six ways to save abrasive in sandblasters, they are: segregator, ash separator, recovery device, spray gun, sandpipe, and pressure.

Segregator

Segregator is a most important part in saving abrasive. There are generally two kinds of segregators, one is pneumatic separation, the other is mechanical separation. The former is often employed. Before purchasing sandblasters, purchasers had better inform the factory with accurate abrasive types and grit sizes to make sandblasters more exquisitely controlled.

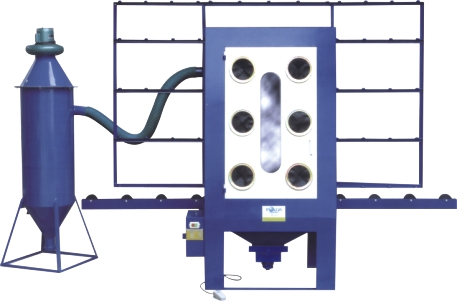

Ash Separator

The air quantity of an ash separator leads directly to abrasive loss. Before using a sandblaster, the operator should fix the ash separator to a most appropriate place. The filter drum inside the ash separator should be cleaned at regular intervals. The waste sand in the wind scoop of the ash separator should also be cleaned.

Abrasive Recovery Device

There are two kinds of abrasive recovery devices, one is pneumatic recycle, the other is machinery recycle. If a sandblaster uses non-metal abrasive, then pneumatic recycle is suggested; if metal abrasive is employed, then both kinds of recovery devices are available. Because non-metal recovery is likely to smash abrasive to pieces.

Spray Gun

Spray gun abrasion will consume much abrasive. So when using a spray gun, the operator should check each part of the spray gun at timely intervals. Once abrasion is checked out, the spray gun should be replaced in time to avoid abrasive waste.

Sandpipe

Many specialists has not realized the abrasion of sandpipe. In fact, sand pipe is of some influence to the abrasive loss. The trend of sandpipes will lead to the direction of abrasive jet flow. So each sandpipe of sandblasters should be kept from bending.

Pressure

The pressure is closely related with the sandblaster's efficiency and the abrasion degree of abrasive. Accurate data should be figured out based on users' demand for products and materials, such as aluminum products, the oxidation treatment should be under pressure of 4 kilos.

Author: Liwei Chu

Copyright: iAbrasive.com–Abrasives & Diamond Tools Market