Vitrium 3 is the latest ceramic bonding agent technology to meet the grinding development demand launched by Saint Gobain Abrasives in 2013.

Vitrium 3 is the latest ceramic bonding agent technology to meet the grinding development demand launched by Saint Gobain Abrasives in 2013. It adopted the advanced particle adhesive technology that endows grinding wheels with the characteristics of super precision and high efficiency. Besides that, it can effectively reduce burn and improve workpiece surface grinding quality as well as working efficiency. So Vitrium 3 can be widely used in traditional alumina oxide abrasive and new ceramic abrasives such as Quantum/TG grinding wheel manufacturing, space and aeronautics industry, auto parts industry, bearing industry, electronics industry, etc.

The new-generation Vitrium 3 bonding agent TG grinding wheel succeeded in steering rack strong grinding tests.

A client has 4 sets of Blohmn powerful grinding machines that are used to process automobile steering rack. Since the previous bonding agent cannot well explain the characteristics of abrasives and sometimes leads to burn, Saint Gobain Abrasives has been doing experiments. Since the new bonding agent—Vitrium 3 was born, the grinding wheels can meet the demand completely due to its special properties. At the same time, Saint Gobain Abrasives have made adjustments to grinding parameters to further prove that the Vitrium 3 grinding wheel can help users reduce processing costs.

Experiment Date: Mar. 2013

Grinding Application: rack rod molding grinding

Experimental Machine Tool: Blohmn

Workpieces: rack rod, 37CrS4, HRC 45

Experiment Conditions: Using the same machine tools, parameters, workpieces, and change the parameter during the grinding process, protecting the profile of the tooth from being burnt.

Experiment Parameter:

Contact roller continuous dressing quantity: from 0.08mm to 0.03mm

Playing surface travelling speed: improve from 170mm/min to 220 mm/min

Standard grinding and cutting parameters:

Grinding wheel load: 4mm

Playing surface travelling speed: 170 mm/min

Contact roller continuous dressing quantity: 0.08mm

Grinding wheel specification:xxx500*200*203.2 3TGU 60/14 GVS3P

Result Analysis

1. After adjustment, the workpiece parameter can fully meet the requirement. The grinding wheel can be used till the end without any damages or burns.

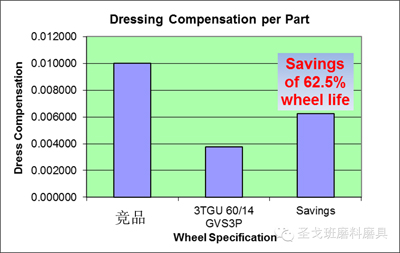

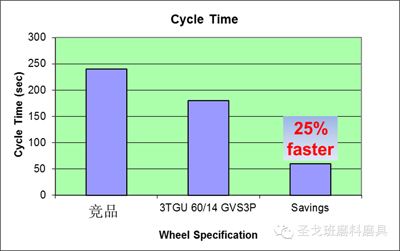

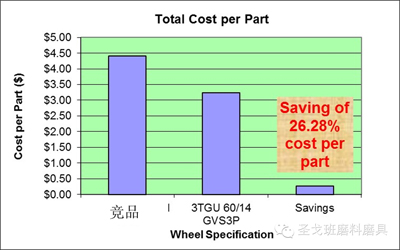

2. Cost savings: since SGA grinding wheel unit price is higher than other grinding wheels, PSP comprehensive cost calculation should be used to show the reduced cost results, as shown in the following pictures:

Reduced grinding wheel dressing quantity has prolonged the service life of grinding wheel by 62.5%

Improved playing surface travelling speed has increased grinding efficiency by 25%

Reduced grinding wheel replacing frequency, declined contact roller continuous dressing consumption rate, and shrinking management costs have contributed to the decrease in comprehensive costs by 26%.

Author: Liwei Chu

Copyright: iAbrasive.com--Abrasives & Diamond Tools Market