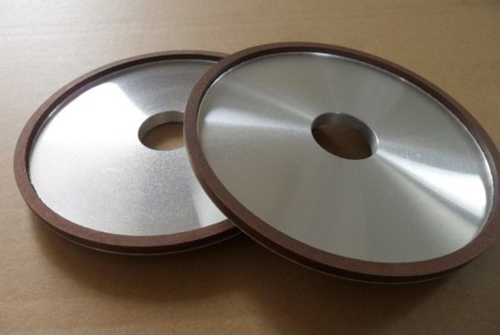

Resin grinding wheel is a kind of industrial products with strong manufacturing technology, and there are some problems on mixing material, forming, hardening and processing of resin grinding wheel.

Resin grinding wheel is a kind of industrial products with strong manufacturing technology, and there are some problems on mixing material, forming, hardening and processing of resin grinding wheel.

A. The mixing material process: The key of mixing material is uniformity, and the molding material should reach: uniform composition distribution. It should stay loose, no significant powder leakage, and the materials should be spread evenly, with good formability.

B, The forming process: Currently, most of domestic eveners are rotating eveners, but their limitation make manufacturing enterprises’ operators hard to operate, position tolerances and out-of-tolerance of static balance.

C, The hardening process: This is the most critical production process, which is easy to cause quality problems. There are two factors: The temperature difference of curing oven and calcining kiln is too big; The way to feeding is improper. The temperature difference of hardening furnaces is too big, which causes the deviation from the hardening curve of hardening resin grinding wheel, and the quality of grinding wheel hardening not fully guaranteed.

D, The processing operations (mostly for large diameter high thickness resin grinding wheel) : Resin grinding wheels, especially for large diameter and high thickness or strict size tolerance grinding wheels need to carry on the processing after hardening, to ensure the geometry size and position tolerance of grinding wheel.

To view more resin grinding wheels, please visit the following two resin grinding wheel manufacturers: Luoyang Xiwei Abrasives Co., Ltd. and Beijing Dongmao Glass Machinery and Tools Co., Ltd.