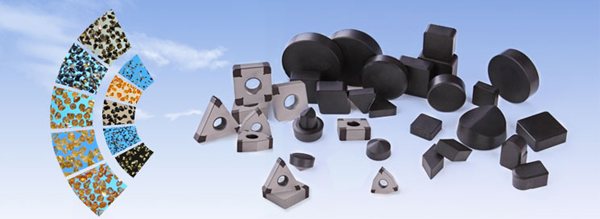

Cubic boron nitride cutting tools were used as cutting tools in 1970, and its good workability and high speed cutting performance, make it become great cutting tool material for processing high hardness materials and difficult-to-machine materials.

With the continuous development of modern technology and cutting technology, a lot of cutting tool materials tend to appear. The development of cutting tools: high speed steel cutting tools – cemented carbide cutting tools - coating cemented carbide cutting tools - ceramic cutting tools - cubic boron nitride cutting tools.

And cubic boron nitride cutting tools were used as cutting tools in 1970, and its good workability and high speed cutting performance, make it become great cutting tool material for processing high hardness materials and difficult-to-machine materials.

A, High hardness and good wear resistance: The hardness of cubic boron nitride cutting tool is second only to diamond cutting tool, which are both collectively known as superhard cutting tools. Because of its high hardness, it also makes cubic boron nitride cutting tools with good abrasion resistance.

B, High thermal stability: Its thermal stability can reach 1400 ℃ ~ 1500 ℃, more than that of diamond (700 ℃ ~ 800 ℃). It is the highest thermal stability in the cutting tool materials, so it can process high temperature alloy materials.

C, Good chemical stability: It does not react with iron material under 1200 ℃ ~ 1300 ℃.

D, Good thermal conductivity: The thermal conductivity of cubic boron nitride (79.54 W/m.k) is second only to diamond (146.5 W/m.k). With the increase of cutting speed, the coefficient of thermal conductivity of cubic boron nitride also is gradually increased. This is helpful to decrease the temperature of cutting zone and reduce the diffusion wear.

With the widely application of cubic boron nitride cutting tools, high hardness and difficult-to-machine materials becomes easy to process. It also shows that as long as the cutting tool industry constantly develops with the development of times, to develop a number of high quality, high performance tools or combined tools, it can make profits for the company, and further promote the development of China's manufacturing industry.