Abrasive belt grinding can solve large surface grinding and complicated surface grinding that cannot be solved by other abrasives products.

1. Abrasive belt grinding can solve large surface grinding and complicated surface grinding that cannot be solved by other abrasives products. Besides the materials that can be processed by grinding wheels, abrasive belt grinding can process non-ferrous metals, such as copper, aluminum., and non-metal soft materials, such as wood, leather, plastics, etc. The "cold state" grinding effect during heat-resistant and different-to-grind-materials processing makes abrasive belt grinding unique.

2. Abrasive belt grinding has a high grinding efficiency and small heat accumulation so the workpiece is not prone to be burnt. The high surface quality of abrasive belt grinding is reflected in small surface roughness and no micro flaws on the surface.

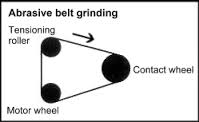

3. Abrasive belt grinding equipment is easy and safe to operate. Abrasive belt grinding produces low noise and little amount of dust. Since the weight of abrasive belt is light, it is easier to control the balance than grinding wheels. Besides that, the flexible grinding effect of abrasive belts can reduce vibration and impact substantially.

4. Abrasive belt grinding consumes less power. So it is both energy-saving and environmental friendly. The bigger the abrasive belt grinding ratio, the higher the power availability of machine tools and the grinding efficiency. Abrasive belt grinding machine is easy to handle because the light abrasive belts and the small grinding force that produces small range of vibration. Since abrasive belt grinding usually adopts rubber contact wheels, it makes lower noise, generally lower than 70dB. Therefore, abrasive belt grinding is environmental friendly.

A Comparison between Abrasive Belt Grinding & Traditional Coated Abrasives Grinding

In traditional coated abrasives grinding, abrasive grains are evenly spread on the substrate's surface by a single layer. Abrasives for coated abrasives are even in particle sizes, which is an important factor of high efficiency and cold state grinding of coated abrasives. A typical difference between abrasive belt grinding and grinding wheels is that the former operates by improving grinding stress, not by improving abrasive belt velocity. The linear velocity of abrasive belts is usually between 15m/s to 35m/s. While grinding wheels operate by improving tensile stress, so abrasive belt grinding is useful in strengthening workpiece surface and improve workpiece fatigue strength.

Currently, coated abrasives are developing towards special purpose, precision, and high efficiency, which features high-speed, powerful, and heavy-duty grinding. The theoretical basis of abrasive belt grinding is Quick-point Grinding, an advanced high-speed grinding technique developed by Mr. Erwin Junker from Junker, a German company, in 1994. Integrating high-speed grinding (Speed is over 90m/s), CBN superhard abrasives and CNC flexible machining technologies, the theory has a good performance and serves as a new breakthrough in ultra-high speed grinding technique. So far, the technique has been applied in the auto industry, the shipbuilding industry, and tools manufacturing industry in foreign countries. China remains dependent on import. Therefore, keep pace with internationally advanced technology is of great significance to improving manufacturing technology and equipment manufacture standard in China.

Author: Liwei Chu

Copyright: iAbrasive.com--Abrasives & Diamond Tools Market