Over the last decade, flap discs have been the fastest growing abrasives category in metal fabrication due to excellent performance in various applications. iAbrasive gives a few suggestions on how to select the right flap discs.

Over the last decade, flap discs have been the fastest growing abrasives category in metal fabrication due to excellent performance in various applications. Flap discs are popular for several features: light in weight, easyto control, less vibration and resulting fatigue as well as reduced noise. However it is important to know how to select the right one by understanding all the variables and how they apply to metal fabricating application. iAbrasive just gives a few suggestions by explaining the five variables of flap discs.

Shape

Designed with a hub that allows work to be done on the face (flaps), which can be applied to the work at an angle or flat, flap discs are used almost exclusively on right angle grinders. Conical shape (Type 29) or a flat shape (Type 27) provides different performance features.

Type 29 Conical flap discs are the best choice for aggressive stock removal. Conical flap discs have angled flaps and may be used on both contoured and edge work, whose angle provides greater surface contact for stock removal on flat surfaces. They are the best choice when speed and stock removal are primary considerations. While Type 27 Flat flap discs are the best choice for finishing. Flat flap discs are used primarily on flat surfaces. They are the best choice for blending and smooth finishing.

Backing Plate Material

The second major question is what type of backing plate to use. All flap discs are a combination of abrasive flaps adhered to a rigid backing plate. It is the backing plate that provides stability during operation. There are three different material types:

Fiberglass backing plates help to absorb vibration and are consumed during use, with no smearing. Fiberglass is the most popular material because of its high strength and light weight.

Plastic backing plates are becoming more popular due to some conformability as well as being trimmable, which allows more use of the flaps, especially for blending and finishing. Aluminum backing plates are the least popular, but are good in applications demanding extra high strength and rigid support. While not consumable during use, an aluminum plate can be recycled.

Abrasive Flap Density

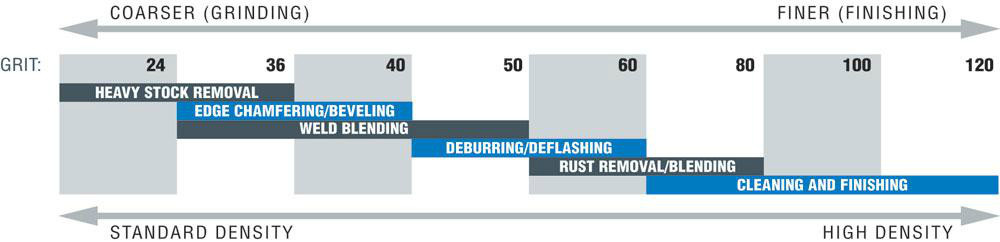

The quantity, angle and spacing of the flaps on the backing plate vary substantially. This is referred to as the density of the flaps. It is important to match the flap density below with your application, if possible, to achieve the best results.

Standard Density flaps are excellent for heavy-duty applications and rapid stock removal. High Density flaps are ideal when working on uneven or curved surfaces as well as finer grit blending.

Abrasive Grit

Probably the most important criteria are the type of abrasive on the flap and the appropriate grit size. For metalworking, there are three primary abrasive types:

Ceramic Alumina –the latest innovation in abrasives, this grain micro fractures to allow a continuous supply of the sharpest cutting edges. This provides the fastest cut as well as the best utilization of the entire grain for the longest life, especially on stainless or high alloy materials.

Zirconia Alumina – an excellent blend of zirconia and aluminum oxide grain which provides a very good cut rate to cost ratio. This is a very good choice on carbon/mild steel applications.

Aluminum Oxide – the original metalworking abrasive, this product is recommended for smaller jobs where a consistent, low cost product is needed.

Grit Size

Grit size is the last component you need to select to match your application. The grit recommendation chart below can help to select the grit size needed.

Learning about the five variables will help you pick the correct one. Most manufacturers offer a broad stock line of 4 in to 7 in to fit all popular right angle grinders. Some also offer custom manufacturing of flap discs to meet specialized or high-production applications. Be sure to consult your sales representative to help evaluate their total line to provide you with the best grinding, blending and finishing solution for your metal fabrication application.

See more at: http://www.iabrasive.com/articles.