There is a clear requirement for 3D printing polishing film. The film is a fine-grit, abrasive material and provides a smooth, mirror-polish finish - much better than that given by sandpaper.

After attending the RAPID 3D event in the summer of 2016, the author has been addressing questions relating to sanding 3D-printed objects. Thanks to the expertise of Fiber Optic Center in abrasive films, a number of technicians and engineers at 3D printing production houses, 3D printer manufacturers, and 3D printing hobbyists, have been asking the author questions concerning 3D printed objects.

Questions Related to Sanding 3D-Printed Items

“I create tabletop prototypes of rockets for a government contractor. To look professional, they must have a high polish. I’m talking luster! Can you give me how-to advice to polish 3D printed objects?”

“My automotive parts company is on the ‘bleeding-edge’ of 3D printing applications. We use an FDM 3D printer to develop our prototypes and finished parts. In order for finished parts to perform properly, we need to get a smooth finish. Do you have sandpapers or abrasive films that provide a smooth finish?”

“As a hobbyist, I am discovering many exciting applications for 3D printing. My struggle is with the limitations of sanding. It’s course, messy and ineffective. I’m looking for advice to use sandpaper or abrasive films for my 3D printing projects to get a polished finish. Is this even possible?”

“I work for a 3D printing production house. Many of our customers need a smooth finish. They are expressing frustration with sandpaper. Can your 3D printer polishing film achieve the degree of smoothness they’re looking for?”

Some of the customers are using 3D printing to create prototypes, which need an aesthetic finish to impress major customers. Other 3D-printed objects are used in the manufacturing sector and require smoothness for functionality purposes. 3D printing hobbyists and professionals are getting frustrated that sandpaper does not offer the luster and smooth polish they require.

3D Printing Polishing Film

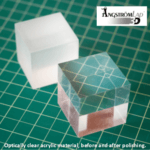

There is a clear requirement for 3D printing polishing film. The film is a fine-grit, abrasive material and provides a smooth, mirror-polish finish - much better than that given by sandpaper. Fiber Optic Center is an expert in fine-grit abrasive films and fiber optics, and the company exclusively offers 3D polishing films that provide a mirror-polish finish for the 3D printing industry.

Fiber Optic Center’s ultrafine 3D printing polishing films are available in grit sizes as small as 1 micron (see chart below) - 10 times smaller than the finest super-fine microgrits available at local hardware stores. This makes it possible - and surprisingly easy - to realize a glossy, smooth polish on the 3D-printed object.

Shown below is a fused deposition modeling (FDM) 3D printed object before and after polishing. The inferior infill near the top of the dome becomes more obvious after polishing.

Tips to Polish 3D-Printed Objects

Polishing a 3D printing project is a relatively quick process. For instance, using Fiber Optic Center’s ÅngströmLap 3D Polishing Films, it takes about 15 minutes to polish a print roughly the size of a TV remote. Some tips to achieve best results are given below:

Start With a Good Print Job

The smallest layer height (highest resolution) of the 3D printer should be used. On several printers, this is 0.1 mm or less, and is especially important for the outermost layer. Sanding and polishing processes remove some material from the surface, which can reveal voids caused due to incomplete filling of the underlying layers. It is better to plan to use 100% infill to fill the surface voids. For finer features, slower printing speeds need to be used.

Gradually Decrease Grit Size When Sanding and Polishing

Whether the composite polymer is a metal, rubber, or thermoplastic, the sanding and polishing process is similar to sanding wood. The rule of thumb is to progressively decrease grit sizes until the desired smoothness is obtained. The grit sizes of the ÅngströmLap ultrafine 3D printing polishing films are as small as 1 micron - 10 times smaller than the finest super-fine microgrits available at a local hardware store.

Wet-sanding Provides More Luster

To achieve a glossy, smooth finish for 3D printed objects, wet-sanding provides a major advantage. For instance, automotive paints have a mirror-smooth look, and such luster is achieved by wet-sanding. Wet-sanding eliminates large scratches that remain after the dry-sanding process. Additionally, water acts as a lubricant and carrier for the sanding dust.

Fiber Optic Center’s ÅngströmLap 3D Polishing Films are specifically designed for polishing 3D-printed objects and can be used dry or wet. Their durable, waterproof plastic backing makes them espcecially amenable to wet sanding. The films can be rinsed or soaked in water if they get clogged. (This provides a more robust, durable solution than sandpaper.)

Additionally, several ÅngströmLap 3D finer grits are unique “cushion films,” as they possess a specifically designed cushion layer that provides a very slight give to the film. This allows the film to conform to the surface better. The cushion films provide greater surface area and better smoothing action for the grit.

Tightly graded aluminum oxide and silicon carbide spheres act as the grits, which have high durability and hardness. One of Fiber Optic Center’s finest films, 1-micron SiC, is specialized for mirror polishing (refer to the chart below).

Using ÅngströmLap 3D Polishing Films

The following steps can be used to sand a 3D printing project:

Begin with the largest grit to remove all pits, scratches, and bumps. Most polymers are easy to sand, so there is no need to overdo it. However, it is important to sand until odd divots or bumps are not visible. Sanding needs to be done evenly across the surface in small circular movements. The first grit will take the longest, will look the worst, and is the most crucial step. Good light conditions is required and the surface needs to be inspected carefully. If any scratches are missed that are deeper than the ones that are being made with the grit being worked with, they will become prominent as the process is carried on, and there may be a need to start all over again. Rinsing the 3D printed object can help to detect the missed pits, scratches, and bumps.

Initial sanding and polishing is generally done dry. However, the process can be switched to wet-polishing/wet-sanding at any point by soaking or rinsing the 3D polishing film in water. If the goal is to realize a glossy finish, then wet polishing must be included as finishing stages in the polishing process.

When the surface found to be even, a finer grit abrasive film can be used until the desired surface finish is obtained. The ÅngströmLap 3D Polishing Films are available in a number of grit sizes: Very Fine, Extra Fine, Super Fine, and Ultra Fine. These abrasive films help to realize a mirror-polish finish that is difficult (if not impossible) to get using a sandpaper.

If a high-gloss luster is needed when sanding the 3D printed object, the ÅngströmLap 3D Polishing Films can be experimented with. The fine-grit films could provide the solution to realize a smooth, mirror-finish polish for the 3D printing projects.