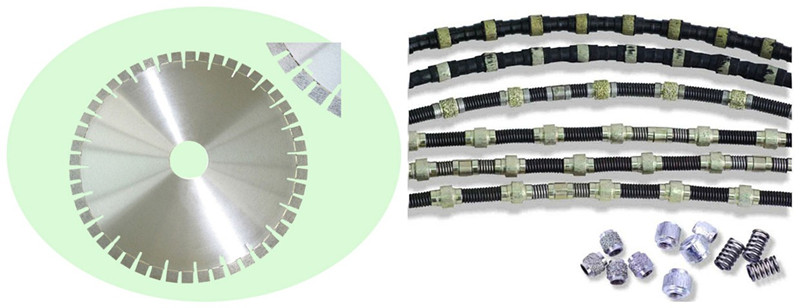

Compared with diamond saw blades, diamond wire saws have their own features which make them widely used in stone processing.

Raw Stone Processing

Stones directly got from mines with irregular form and rough sections are called raw stones, and can not be applied into plate processing immediately. They must be shaped primarily. At present, raw stone processing in China mainly refers to the process of marble and granite. With the development of technology, taking advantage of human resources to shape stones has been outdated.

Diamond saw blades used to process raw stones usually own a large circular saw blade, on which diamond grits are inserted. Owning to its flexible application, diamond saw blades can be used to process ultra-hard stones. While, its diameter of saw blade tends to be large, and its height is about twice of stones waited to be processed and plus the diameter of Flange. However, it is not very easy to manufacture diamond saw blade with too large diameter. Therefore, diamond saw blades are unsuitable to process oversize plates.

Comparatively, diamond wire saws not only own the flexibility of ropes, but also own rigidity of diamond. Moreover, they are not limited by length. Due to those features, diamond wire saws are almost applicable to cut any large objects. It has many advantages to use diamond wire saws, such as short time preparation, strong flexibility, high efficiency, energy saving, etc, which makes diamond wire saws popular in stone mining and stone processing.

Plate Cutting

When processing stones, plate cutting is a quite important step. Usually, diamond saw blades are used to cut plates. But in this situation, the size of plates is relatively small. If applying diamond wire saws, the results are difficult. One diamond wire saw is able to cut large plates and ultra-large plates, and will not be restrained by the thickness of stones. However, compared with diamond frame saws containing several tens or a few hundreds saws, diamond wire saws’ efficiency is low and cost is high. Consequently, diamond wire saws are used when plates are too thick or their amount is small. However, with the development of technology, the combined diamond wire saws are shown up. The combined diamond wire saws could be applied into cutting marble and granite plates conveniently when changing different beads or change linear velocity of diamond wire saws, which are advantages frame saws lack.

Irregular Stones Processing

Irregular stones refer to all special-shaped stones except sheet and block stones, and include many varieties, such as pillars and arches. Nowadays, people’s demands are much stricter, so as to irregular stones processing. In the course of irregular stones processing, what mainly used are diamond wire saws and diamond saw blades. Owing to its high linear velocity, diamond wire saws could shift curve type and arc type, and can be widely applied into processing parquet and curved sides.