Diamond wire saws are widely used in stone mining. Here, advantages and disadvantages of diamond wire saws and how to choose proper diamond wire saws are discussed in this article.

China enjoys rich natural resources in vast land, and stone is one of them. In our country, there is a number of stone mines distributed widely. With rapid development of stone industry, the requirement of the size of raw stone is much stricter than before, which pushed the upgrading of mining technology. Facing different kinds of rocks, how to reduce the cost and improve the rate of usable stone have drawn practitioners’ attention.

The traditional blasting method of stone mining mainly relies on the local residents. Without researches and plans, as long as they have air compressors, rock drilling machine, wheelbarrows, and tripodal, they dare to mining. In this situation, the formation rate of raw stones is quite low, and there is nobody responsible for the treatment of a large amount of waste residue. As a result, the wastes destroyed the vegetation. Moreover, because the technology is backward, the quality of what they got is not very high. What’s worse, the real good mine is damaged or buried by their actions. Therefore, at the beginning of 1980s, some countries which have advanced technology in stone mining had forbidden mining stone by the way of explosion.

In addition to explosion, what are often used including the cutting of flame machine, static fragmentation, the use of diamond wire and stone cutting machine. Every method has its own feature and is suitable to different circumstance. Limited by space and time, the application of diamond wires saws is mainly discussed in this article. At present, diamond wire mostly used in mining marble, limestone, travertine and other stones with low hardness. Its application of granite is also increased.

(1) Marble Mining

Diamond wires are mainly used to mining soft mining geology, such as marbles. In some marble mines employed advanced mining technology, they tend to combine diamond wire saws with chain splitter saw. They are complimentary to improve the efficiency. Up to now, it is the best choice to separate marbles.

(2) Granite Mining

Taking the cost and performance of diamond wire into account, in the process of granite exploitation, diamond wires saws are usually used to separate one or two vertical side from orebody. As for the back side of vertical profiles and horizontal bottom underside, currently they mainly depends on downhole rock drills and explosion.

Advantages and Disadvantages of Using Diamond Wires Saws

Advantages of diamond wires are as follows: applicable to various landform, small weld , fast cutting speed, applicable to cut big block,etc. Compared with traditional explosion and combustion flame method, the application of diamond wire can avoid wasting resources, noises, pollution and high energy dissipation.

Disadvantages: In order to use diamond wire saws, it is essential to ensure power and water supply and convenient traffic, and before using diamond wire, it is a must to drill holes. The thickness of ore bed must be over 500mm. Additionally, the operator must be proficient.

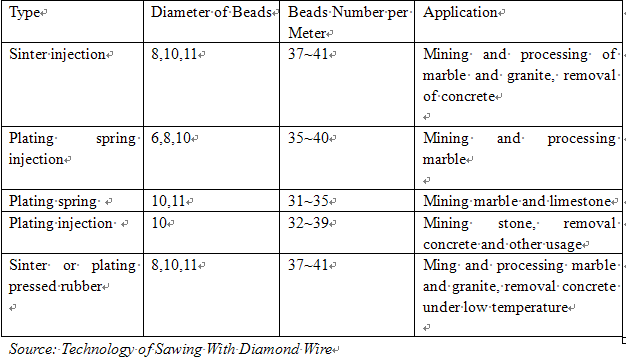

Types Diamond Wire and Purposes of Using Diamond Wire Saws

When choose diamond wire, the features of stone should be considered for the purpose of fulfill its potential. For example, in the process of marble mining, because of the main composition of marbles is calcium carbonate, and does not contain quartz, sawdust won’t erode rope and beads. Therefore, when mining marbles and limestone, it is often used plating beads, and in the process of exploit granite, sintering beads are referred.

P.S. iAbrasive.com will regularly update the knowledge of abrasives involving how to choose proper abrasives and tools, how to use and maintain them in the future. Don’t forget to follow us.