In terms of material, the market can be segmented into ceramics, carbide, diamond, cubic boron nitride, and others. In terms of application, the market can be segmented into grinding, cutting, polishing, milling, drilling, and others...

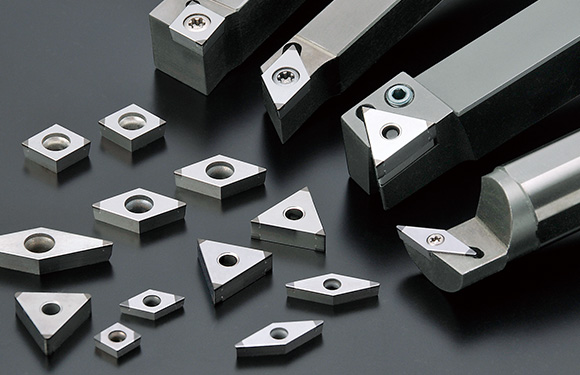

Inserts are nothing but large-sized pieces of abrasive materials that are obtained by sintering a precursor powder into a consolidated mass. For instance, the crystal particles of diamond and synthesized cubic boron nitride (CBN) cannot be used directly in any kind of tool, except as embedded particles in polishing pastes for finishing purposes. These inserts are available in various shapes such as disks, rhombus, and triangles. The shape of the insert required in a tool is determined by the type of application.

Cutting tool inserts are primarily prepared from materials such as ceramics, carbides, diamond, and CBN. Among these, diamond and CBN are classified as superabrasives due to their property of extreme hardness. Most commonly used cutting tool inserts are manufactured from ceramics (such as ceramic aluminium oxide and ceramic iron oxide) and carbides (such as silicon carbide (carborundum) and boron carbide).

Inserts are required for cutting tools that are consumed by several end-user industries such as machinery, electrical & electronic equipment, transportation, construction, metal fabrication, and medical devices. The medical industry is anticipated to be an end-user industries that is likely to provide ample opportunity to drive the superabrasives market forward. The automotive and aerospace industries are expanding rapidly. This, in turn, is estimated to drive the overall cutting tool inserts market due to their requirement in the manufacture of transmission components, engines, brake rotors, gears, bearings, and other components.

Computer numerical controlled (CNC) machines are machine tools that are controlled by computers executing pre-programmed sequences of machine control commands. CNC machines provide flexibility for manufacturing, as they can be programmed to perform certain actions on a piece. CNCs can have up to 12 holders and coolant pumps to cut down on tool damage and wear. CNC machines employ indexable tools and drills that assist in cutting and altering metals, which a manual machine is not capable of. They are capable of making clean, precise, and fast cuts through metals and other hard materials. CNC machines help in computer-aided design (CAD) and computer-aided manufacturing (CAM) by assisting the developer through the entire process. Usage of the CNC machining technology is increasing due to demand for superior-quality products and subsequent surge in automation. The technology is rapidly being utilized for machining by diamond as well as CBN.

In terms of material, the market can be segmented into ceramics, carbide, diamond, cubic boron nitride, and others. In terms of application, the market can be segmented into grinding, cutting, polishing, milling, drilling, and others.

In terms of geography, the cutting tool inserts market can be segmented into Asia Pacific, Europe, North America, Latin America, and Middle East & Africa. Asia Pacific is the hub for a large number of manufacturers of cutting inserts. In terms of consumption as well as growth potential, Asia Pacific dominated the global market, and is expected to continue the trend in the near future. This trend is ascribed to the technological advancements in the automotive, medical, and aerospace industries observed in developing countries in Asia Pacific. Latin America and Middle East & Africa are likely to account for comparatively minor shares in the global market due to the lack of manufacturing facilities and their export-oriented economies. In Europe and North America, the former is estimated to witness higher consumption of cutting tools inserts than the latter.

Key players operating in the cutting tool inserts market include 3M, Saint-Gobain, Element Six, Sandvik AB, NanoDiamond Products, KYOCERA Corporation, Tomei Diamond Co. Ltd., ISCAR LTD., ILJIN DIAMOND CO. LTD., SHOWA DENKO K.K., and Asahi Diamond Industrial Co. Ltd.