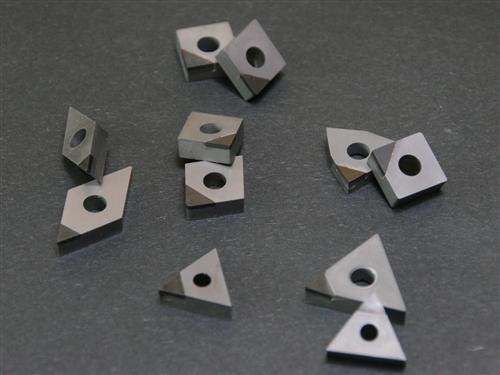

CBN cutters include two categories – CBN profile cutters and CBN cutter blades. CBN profile cutter is made by welding CBN composite bed onto profile cutters.

Cubic boron nitride (CBN or c-BN) is widely used as an abrasive. Materials with cubic boron nitride crystals are often used in the tool bits of cutting tools. CBN cutters include two categories – CBN profile cutters and CBN cutter blades. CBN profile cutter is made by welding CBN composite bed onto profile cutters. Following is a list of advantages of CBN profile cutters.

1. High intensity and wear resistance

The micro-hardness of CBN is about 8000 to 9000HRC, second to diamond (9000 to 10000HRC). Besides that, CBN cutters have a wear resistance that is much higher than hard alloy, ceramics, and diamond cutters, which enables it to process hard cast iron and steel workpieces with high intensity, hardness, and thermal sensitivity.

2. Good thermal stability

CBN's usefulness arises from its insolubility in iron, nickel, and related alloys at high temperatures, whereas diamond is soluble in these metals to give carbides. CBN can withstand temperatures as high as 1400 to 1500 degrees centigrade, and will keep its hardness under 1200 degrees centigrade. When used in high-temperature alloy processing, CBN cutters have four to six times in cutting velocity compared with hard alloy.

3. Excellent thermal conductivity

The thermal conductivity of CBN is much higher than super steel, ceramics, and hard alloy. The coefficient of CBN cutters' thermal conductivity increases with temperature rise.

4. High chemical stability

CBN has a high chemical inertness. It only reacts with carbon under 2000 degrees centigrade, so CBN cutter is suitable for ferrous metal processing.