The world's first Hybrid grinding machine-MillGrind of Hybrid Manufacturing Technologies is available now.

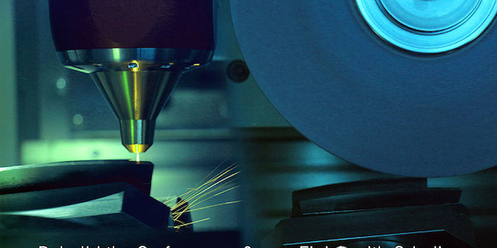

The world's first Hybrid grinding machine-MillGrind of Hybrid Manufacturing Technologies is available now. The first hybrid grinding machine on the market was in the debut at the Paris air last week, which sets a new standard for grinding machine industry. MillGrind are products of research and development by German ELB Grinding Machine Co., LTD with Hybrid Company, which is a continuous correction wriggle grinding machine equipped with Ambit laser metal deposition and the milling function.

The design inspiration of this mixer comes from Markus, Dr Stanik. He also plays a key role in the process of Hybrid Company in 2013 to create the world's first Hybrid MillGind machine.

Dr Stanik comments: "the grinder reduces the required number of made parts for installation, which has higher flexibility. We believe that it is of great benefit to customers with the metal and milling function and surface precision grinding and forming precision grinding combined. This machine that has multitasking functions can be better able to help people save time and cost, especially suitable for aerospace applications."

CEO of Hybrid Company, Jason Dr Jones adds: "We cooperate with ELB to produce the world's first Hybrid grinding machine, and we feel very honored. The machine can make automatic conversion in the precision grinding, milling and AMBIT metal deposits, which makes it stand out in many similar products.

Perhaps the most exciting thing is that now we are in the process of increasing material manufacture some parts, and you can finish the surface processing of the precision grinding."

The popular opinion is that the cost of grinding is higher than that of the milling, but if it can be effectively used, grinding can not only guarantee the quality of surface processing, but also remove material more significantly at a higher cost performance, especially in processing some materials that are not easy for processing, such as nickel-based super heat resistant alloy.

MillGrind is equipped with conventional abrasives (carborundum) with superhard materials performance and 1/10 micron XYZ resolution. The transformation between grinding wheels can be completed in seconds, and 8000 revolutions per minute of spindle can be automatically loaded milling cutter, used for drilling, tapping and other milling operation.