The main countries that produce synthetic diamond in the world at present: the United States, South Africa, Ireland, Sweden, the United Kingdom, Germany, Russia, Ukraine, Armenia, Japan, China, Romania, Poland, the Czech republic, Korea, Greece and India, nearly 20 countries. The output of synthetic diamond production is of 0.7-1 billion carats, and the annual output of America, Britain and Russia of them have been over 100 million carats.

The annual output of synthetic diamond in China has been more than 200 million carats, ranking first in the world. The world annual growth rate of synthetic diamond production is of 8%-15%. GE company in the United States, DeBeers in Britain and Winter company in Germany are three big groups that produce synthetic diamond in the world, dominating the production technology and consumer market of synthetic diamond and representing the development direction of synthetic diamond in this world. More related content can be inquired from diamond industry market research and analysis report.

GE first announced in 1955 that the industry method of synthetic diamond, and was once in a leading position in monocrystalline technology, and compared with other two companies at present, their polycrystalline technology is more advanced, with the annual output of 165 million carats and the compressing press tonnage adopted by the general is between 38-100MN.

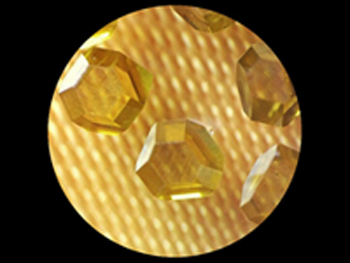

De Beers Company produced the world's largest gem-grade monocrystalline (11.14 carats) and industrial-grade monocrystalline (14.20 carats) in 1987, and created a new world record about synthetic industrial-grade monocrystalline diamond of 39.40 carats in 1992. It first introduced the SDA series of saw blade-grade synthetic diamond, and now the SDA series have become internationally accepted grade standard of saw blade-grade synthetic diamond.

DE Beers Company's factories located in South Africa, Ireland and Sweden, are using 100MN compressing press to produce for production, and the inside diameter of high pressure mold cavity is of Φ110 mm. if they use SDA process, the synthesis single output will be 300 carats, with SDA level products of 60%; if they use MDA process for production, the single output will reach 500 carats. In early years, Winter Company is mainly engaged in the manufacture of diamond tools. In order to put the synthetic diamond and diamond tools together as a complete series of products, in 1974, with the support of German government and the north Atlantic treaty organization they began to develop production technology of synthetic diamond, and catch up from behind, whose unique technology and equipment in the production of diamond make their products quality better than the other two companies. For example, the impurity content of products is of 2 ‰-3 ‰, and single output can reach 800 carats, with world advanced level. In our country we have successfully developed the first synthetic diamond since 1963. We put into industrialized production from 1966 but the annual production is of only 10000 carats.

After 30 years of development, we already have more than 600 enterprises that produce synthetic diamond at present, with the annual output of more than 200 million carats. From a point of output, we have become a major country of synthetic diamond production in China. We have our own design and manufacture on synthetic diamond equipments, and one of them is cubic press at present-6 x6MN press, which was put into use before the mid-1980s, and now most of them (about 400) are facing elimination.

The essential equipment is 6 x 8MN press, and now there are several factories that produce and sell 6 x 12MN press, which will be the main selected models of new presses in the future. In mid-to-late 1980s, about 20 pressure machines were introduced, and most of them were belt-type presses below 25MN. Only a few 50MN presses were introduced by individual manufacturers, and they all have the problems about further digestion and absorption for raw materials, the main spare parts localization and so on. Domestically produced belt-type press has been in the development, and 25MN press has been put into production. We also make a breakthrough progress about 60MN belt-type press, whose control technology has been higher than 25MN press, and Φ 65mm large spiral super-high pressure mould has synthesized diamond.