Before making use of grinding wheel it is essential to dress diamond grinding wheel. Presently the common used dressing methods of diamond grinding wheels are not only time-consuming but also losing diamond particles and with low shaping accuracy.

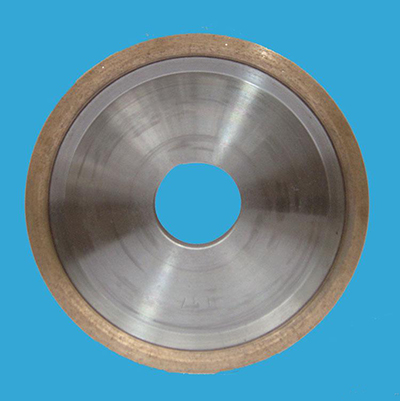

Bronze is mainly used as metal bond in sintered grinding wheel. Through sintering, the combination has high strength, good formality, high temperature resistance, good thermal conductivity, good wear resistance, long service life, and can withstand great load. Because of the inevitable shrinkage and deformation in the sintering, before making use of grinding wheel it is essential to dress grinding wheel, which is hard to operate.

Presently the common used dressing methods of diamond grinding wheels are not only time-consuming but also losing diamond particles and with low shaping accuracy. In recent years, scholars successively have carried out researches on taking advantage of special method to dress diamond grinding wheels with metal bond, which mainly are electrolytic dressing method, spark trimming method and composite trimming method. However, all those methods have advantages and disadvantages. Electrolytic dressing method is fast, but the shaping accuracy is not high; Spark trimming method is slow but with high shaping accuracy and can shape and become sharp simultaneously; the composite trimming methods can be further classified into electrolytic and spark trimming and mechanical chemical trimming method. The effect of composite trimming is good, but the whole system is complicated. As a result, the dressing of sintered diamond grinding wheels still faces difficulties and remains to be solved.

Additionally, the manufacturing process of grinding wheel determines that the morphology of their surface is random. The geometry, distribution and the position of cutting edge of abrasive grains are different, which results that just a few cutting edges could reach the workpiece and restrain the further improvement of grinding quality and grinding efficiency.