In the process of meeting the different needs of foreign customers, we have continuously improved our level of production technology, expanding the applications of silicon carbide.

China's foundry industry has used silicon carbide for many years. From using silicon carbide for metallurgy (just take advantage of its strong reduction), to silicon carbide for cast iron ( emphasize its strong reduction and at the same time, also realize its function of nucleation of graphite crystallization), it is a process that technologies have been improved.

We are the main production country of silicon carbide, and also a major exporter. In the process of meeting the different needs of foreign customers, we have continuously improved our level of production technology, expanding the applications of silicon carbide.

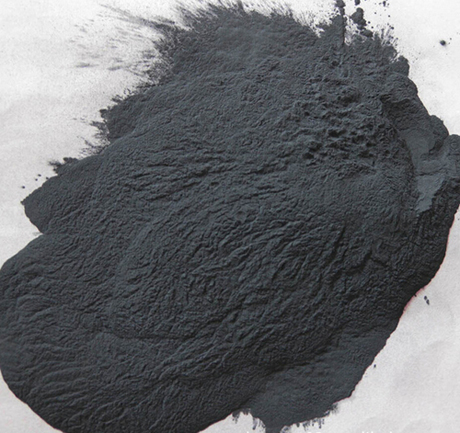

Both metallurgical grade silicon carbide with strong reducibility, and silicon carbide with strong reducibility and intense lasting nucleation of graphite crystallization, are inevitable leftover bits and pieces in the process of producing silicon carbide, which are produced at low temperature zone in high temperature furnace and not suitable for abrasives.

After these leftover bits and pieces are broken, they can be used for reprocessing depending on different requirements. The beneficiated materials used in silicon carbide for cast iron are leftover bits and pieces of polysilicon in the pv industry through proper processing.

According to different production conditions of gray cast iron and nodular cast iron, silicon carbide for cast iron, they commonly use different starch, dextrin, sodium silicate, silicate cement clinker etc. to form different shapes, such as pressure ball, press block. In the actual production process, if there is high quality recarburizer, the effect is much better.

Because it is " leftover bits and pieces " silicon carbide, the prices of metallurgical grade silicon carbide and cast iron silicon carbide are not high in the past. However, with the increase of market demand and the improvement of supplier's theory of remanufacturing technology, the performance of silicon carbide products is also improved obviously.

Along with the increase in the price of silicon carbide, they do not use cheap silicon carbide to replace silicon iron in order to reduce the production cost.

Some suppliers use fine silt produced in the process of producing silicon carbide and other materials, which is added in silicon carbide products for cast iron, in order to decrease the production cost. This is not necessarily a good solution. Because such "silicon carbide", has silica and even some pollutants, and pure silicon carbide is decreased obviously.

For more product information about silicon carbide, please visit Qinyang Sanhui Refractory Material Co.,Ltd. and Yichuan Dongfeng Abrasives Co.,Ltd.