This article introduces new field of application of abrasive belt polishing machine from eight aspects.

1. In the process of producing stainless steel castings, abrasive belt polishing machine can be easily used in plane, internal, external and complex surface grinding. Designing a set of abrasive belt grinding head device as functional unit, which can be installed on facing machine. And at the same time, it also can be designed in a variety of special grinding machines. The characteristic of abrasive belt grinding can help easily to solve some difficult machining parts, such as precision machining of super-long, extra-large and plane parts.

2. There are a range of options about base material, abrasives and adhesives of abrasive belt, which can meet to the needs of a variety of purposes. The particle size, length and width of abrasive belt also have a variety of specifications, and are available in rolls, rings, and other forms. For the same kind of workpiece, abrasive belt grinding can be used in a variety of different grinding methods and technological structure.

3. For grinding wheel grinding, abrasive belt grinding is regarded as "cold grinding". Namely, it has low grinding temperature, and the surface is not easy to show burns.

4. Abrasive belt grinding has great system vibration and stability.

5. It has stable grinding speed. The driving wheel of abrasive belt grinding will not have smaller diameter and slower speed, , not like grinding wheel.

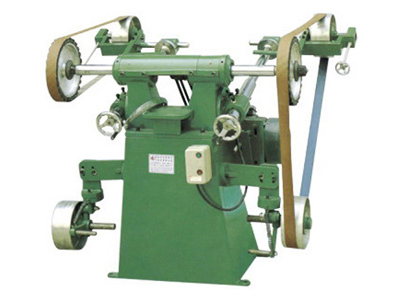

6. There are simple abrasive belt grinding equipment. Compared with grinding wheel grinding machine, abrasive belt grinding machine is much simpler, which is mainly because abrasive belt quality is light, and has small grinding force and little vibration grinding process. The requirement for rigidity and strength of machine tools is far below grinding wheel grinding machine.

7. Abrasive belt polishing machine is easy to operate, less auxiliary time. Either manual or engine driven belt grinding, the operation is very simple. From the replacement and adjust of abrasive belts to the processed workpiece clamping, all this can be done in a very short period of time.

8. Abrasive belt polishing machine has now become a relatively complete and self-contained new processing technology. Because of its high efficiency, wide application range, high adaptability, low cost, safe and convenient operation etc., it is popular with buyers. At abroad, abrasive belt grinding technology has made great progress, and its processing object and applications are becoming more and more widely. It can be processed almost all engineering materials.