Diamond exposed on the surface of stone sawing machine will affect the cutting depth of each particle. That is to say, it influences the material removal rate of stone sawing machine.

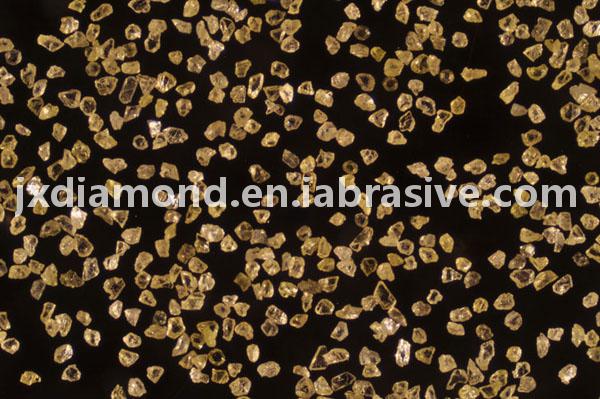

Diamond exposed on the surface of stone sawing machine will affect the cutting depth of each particle. That is to say, it influences the material removal rate of stone sawing machine. The diamond with large particle sizes exposed on the surface will have faster material removal rate. Generally speaking, coarse particle sizes are used for cutting soft materials, while the smaller particle sizes are used for cutting hard materials.

Diamond particle size determines the number of particles per carat. With the increase of particle sizes, the number of particles per carat will also increase. The number of diamonds on the area of stone sawing machine is affected by tool life and power consumption, so choosing appropriate mesh is the key to ensure tool performance. Generally speaking, low concentration of diamond stone sawing machine will use fine-grained diamond, which can make diamond grains on the surface of the cutting tools increased. Thus, it can improve the service life, and at the same time also increase power consumption.

In addition to diamond particle size, the concentration of diamond also determines the number of particle sizes on the surface of stone sawing machine. The higher diamond concentration, the more the number of particle sizes on the surface of stone sawing machine, which is benefical to improve life.