Therefore, we should choose good polishing wheel abrasives and need appropriate processing, and must notice the essential features of the right metal wire drawing craft materials.

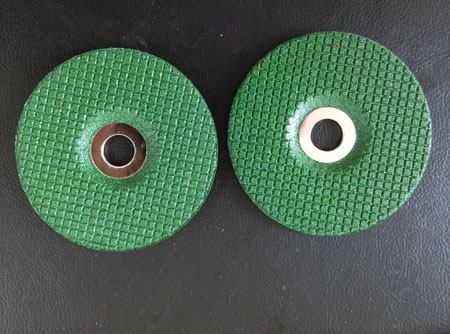

Polishing wheel (wire drawing wheel) of metal drawing craft materials is one of grinding tools in metal workpieces. The grinding way and processing quality of industrial polishing wheel, such as roughness, accuracy and production efficiency, all play a vital role. Therefore, we should choose good polishing wheel abrasives and need appropriate processing, and must notice the essential features of the right metal wire drawing craft materials.

The uniform surface line speed of polishing wheel can get the best polishing effect, so if you use bigger polishing wheel to match with smaller motor, the polishing effect will be affected when linear velocity falls a lot.

The correct ways to use polishing wheel of metal drawing craft materials:

It should make wheel steer toward someone and run at full speed; Make polishing wax on the edge of wheels for a few seconds and let wax attached on the wheels; Hold workpiece to touch wheel surface softly and ensure the workpiece in the center of the wheel shaft below the horizontal plane, otherwise the wheels will be likely to be thrown away from the hands.

The right operation method is to give a gentle touch between the workpiece and wheel surface and then take away, which helps to grind the acute angle on the surface and avoid to produce spots. Add the wax when necessary, but not too much, as too much wax will make the workpiece produce many dark spots. If there is excessive immodesty with wax, please wipe off with iron brush tools and paint again when necessary. Do not force to press the wax on the surface and should make wheel to rotate freely.

When artifacts come into the fine buffing (polishing) process, don't let coarse particles remain in the wheel, otherwise it will produce scratches. When polishing is complete, please use soft cloth with talcum powder to wipe the surface and remove wax. If necessary, dewaxing process should be carried out on the workpiece. A simple try will let you know how to grasp the whole process.

How to use polishing wheel of metal drawing craft materials

Motor power decides the size of the polishing wheel and its shaft must match the aperture of the polishing wheel. The metal wiredrawing craft materials polishing wheel should be in the middle of the shaft, and tightened with a wrench. The uniform surface line speed of polishing wheel can get the best polishing effect, so if you use bigger polishing wheel to match with smaller motor, the polishing effect will be affected when linear velocity falls a lot.