As a new advanced thermal management solutions, it is especially suitable for RF power amplifier and has been proved to reduce the overall package thermal resistance, whose performance has more than other commonly used materials at present.

More and more electronic products begin to flaunt their "fever". In the beginning, the "fever" is to highlight the high performance of products, but later, it turns into a derogatory term of consumers ridicule that product temperature is too high.

The higher the performance of electronic products, the more difficult the thermal management. With the power density of semiconductor components increasing, the heat flux will become bigger and bigger, some even as high as tens of kilowatts per square centimeter that is 5 times than the sun's surface.

If such large calorific value can not be released from components in time, it will become a serious threat to the stability of the electronic products. Some research shows that more than half of faults in the electronic devices are caused by heat related problems. Such as the most common smart phones, although they have a lot of graphite conducting strip and aviation alloy materials, but we still often see some news about the overheating caused by "the world's strongest mobile processor" to burn the motherboard...All these tell us:

As the demand of end products for lightweight and efficient is improved, the development direction of semiconductor solutions is not only the performance, and the heat and thermal performance also have become important factors in the design of semiconductor. Calorific value is mainly in connection with main chip manufacturing process and temperature control algorithm, while the cooling performance can be improved in the material and product structure.

Next we are going to introduce the chemical vapor deposition (CVD) diamond. As a new advanced thermal management solutions, it is especially suitable for RF power amplifier. CVD diamond radiator has been proved to reduce the overall package thermal resistance, whose performance has more than other commonly used materials at present.

CVD diamond is better than traditional heat dissipation material?

As a diamond's immediate family, diamond with "carbon elemental" properties has great ability. Including the highest thermal conductivity, rigidity and hardness, it still has high optical transmission characteristics in a large wavelength range, low expansion coefficient and low density properties at the same time. These features make diamond to be the material thermal management applications that can significantly reduce the thermal resistance.

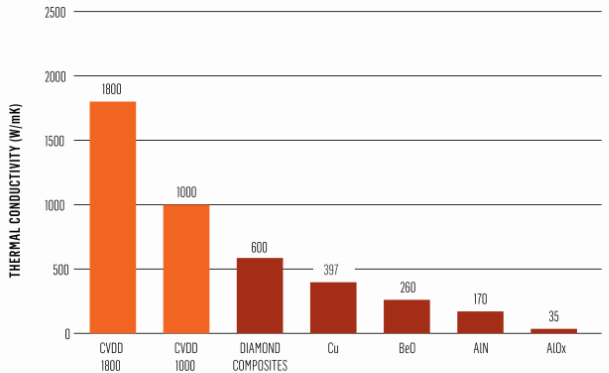

To be the diamond that thermal management applications need, the first step is to select the most appropriate deposition technology. Microwave assisted CVD can better control the grain size and grain interface, resulting in the high quality high reproducibility polycrystalline diamond matching its specific application of thermal conductivity level. At present, the CVD diamond has been commercialized, and 1000-2000 W/M.K thermal conductivity of different levels can be chosen from. CVD diamond has fully isotropic characteristics that strengthen the upward heat diffusion.

As shown in figure 1: thermal conductivity contrast for CVD diamond compared with other traditional heat dissipation material

With the help of recent technological development, CVD diamond has been achieved mass production, and quickly reduces the cost. Without metallization process of CVD diamond radiator production cost is $1 per cubic millimeter, the price mainly depends on the level of thermal conductivity. For common between 0.25-0.40 mm thickness and transverse size that is equal to the application of chip size, the size of RF devices diamond radiator usually less than 5 cubic millimeter. Therefore, only a few dollars of incremental cost needs to be added at the chip that can greatly reduce the system cost. For example, if you can realize the system running at higher temperatures, the initial cost of the cooling subsystem and the continuous operation cost can be reduced. If we are using the appropriate chip paste method, diamond radiator can provide reliable thermal management solutions for semiconductor packaging.