AC3-AC4 is a friable, irregular-shaped, uncoated diamond. The iregularity of the AC3-AC4 surface results in better crystal retention, while high friability enables controlled diamond microfracturing , wheel selfsharpenng and free cutting action AC6 – is a special uncoated diamond, which is tougher than AC4 are used on metal bond wheels for machining hard alloys, ceramics and glass.

d) Type AC for resin Binder coated Ni 56 %

| Type of powders | U.S. Mesh sizes |

| AC4 Ni56 | 325/400; 270/325; 230/270 |

| 200/230; 170/200; 140/170; 120/140 | |

| 100/120; 80/100; 70/80; 60/70 | |

| AC6 Ni56 | 325/400; 270/325; 230/270 |

| 200/230; 170/200; 140/170; 120/140 | |

| 100/120 |

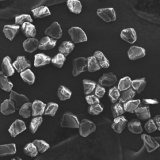

AC4 Ni56 – is AC4 diamond coated with a nickel base alloy to 56 weight percent. The nickel coating enhances crystal retention in the bond. It also reinforces the AC4 crystals to control most fracturing. The coated AC4 requires more power, but the „G-ratio“ improvement is so great, AC4 Ni 56 has become the most widely used product. AC4 Ni56 is known as the standard of the diamond wheel industry for grinding cemented carbides.

AC4 Ni56 – is a special diamond, which is tougher than AC4. It is coated with a nickel base alloy to 56 weight percent. This tougher crystal reduces wheel loading and minimizes workpiece burn when grinding workpieces where more than 1/3 steel is present in the workpiece.