This article introduces the working principle of hot pressed sintering machine.

Diamond tools manufacturers are familiar with this machine-hot pressed sintering machine, which is a kind of special press for producing diamond tools that can sinter 300~3500mm diamond saw blade, diamond segment, diamond honing oilstone, diamond drawing die, etc.

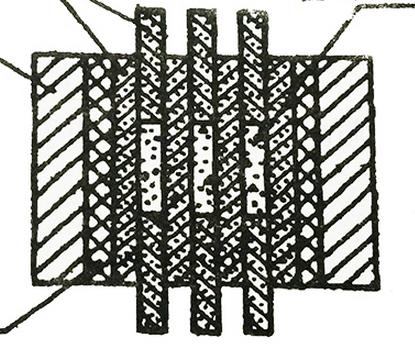

At present, the tonnage and specifications of hot pressed machine are not identical, but its working principle is the same. First of all, we need to put diamond, binder, and other mixture in the mixer into the graphite mould according to certain weight (as shown the above picture, diamond cutting blade is an example), and then put it in the indenter with an electrode, through the hydraulic system to give certain pressure, and at that time, please turn on the heating power and reduce the voltage (4 ~ 6V), the large current (thousands to more than ten thousand) will pass through the electrode head to the workpiece mould. Because graphite mould and metal powder that contains diamond have certain resistance, the large current will produce the heat Q=0.24I2r resistance when it is passing. Finally it can form high temperature as high as 1000 degrees Celsius, which will make metal binder molten at high temperature, and fuse with diamond together under pressure, to produce qualified products.

The pressure specifications of the press are: 15 tons, 20 tons, 100 tons and so on, and the specifications of heating power are: 20kVA、50kVA、60kVA、100kVA、120kVA, etc. The hydraulic system is the same with general press. The current domestic advanced hot pressed sintering machines all use the infrared detecting temperature technology, PC programmable controller of intelligent temperature controller, thyristor power components, and color display technology, which can realize the presetting of temperature and pressure curve, and timely display the tracking pressure, curve of temperature, with high degree of automation, convenient operation and high accuracy of temperature control.