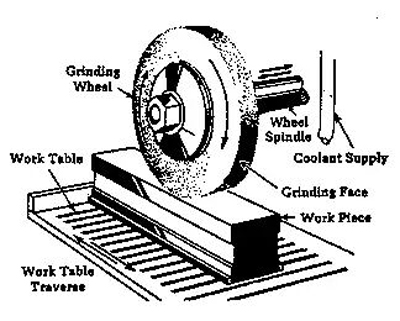

The contact condition of grinding wheels with the workpieces is also a very important factor in the grinding.

The contact condition of grinding wheels with the workpieces is also a very important factor in the grinding. Take cylindrical grinding and surface grinding for example, we can clearly see that their contact areas are different.

If we take grinding wheels in the same particle size for example. Namely, the abrasive particles per unit area have the same numbers, and cylindrical grinding appears to be a line but actually is a narrow face. We assume that this plane has 10 x2 = 20 abrasive grains and the contact face of surface grinding has 10 x4 = 40 abrasive grains.

So we can know that grinding wheel also turned a circle, but the abrasive particles through surface grinding must be higher more than twice as many as external cylindrical grinding. That is to say, the grain size of grinding wheel become finer, and its processing workpiece surface roughness is also better. This is why the external cylindrical grinding grain of 60#grinding wheel can reach Ra0.8, and surface grinding of 60#grinding wheel can reach Ra0.4.

At the same time, we also see that if the contact face is small, its cold speed will be quick, and the cooling fluid can be directly into the grinding zone; If the contact face is large, the cooling liquid is difficult to go directly into the grinding zone, which will lead to poor cooling effect, and is also easy cause some workpieces burning.

If grinding wheel acts on the workpieces in the same grinding force, the force gained from abrasive on the external cylindrical grinding is twice than surface grinding. For example, a total of 100N grinding force, the force gained from cylindrical grinding is 100/20=5N, while abrasives on surface grinding can only gain 100/40=2.5N. Therefore, the binder chain of external cylindrical grinding is easy to fracture, grinding wheel threshing faster. As a result, the hardness of grinding wheel needs to be harder than surface grinding.

For example, the requirements for workpieces is to achieve Ra0.4; materials :45; carbon steel:HRC40-45. If it is surface grinding, please choose the specifications of grinding wheels: WA46K; If it is cylindrical grinding, please choose the specifications of grinding wheels: WA60L.