At present, the manufacturing process of graphene is very slow compared with more traditional electronic materials, which means higher costs. Now, researchers from University of Glasgow find that copper materials used in the manufacture of lithium-ion bat

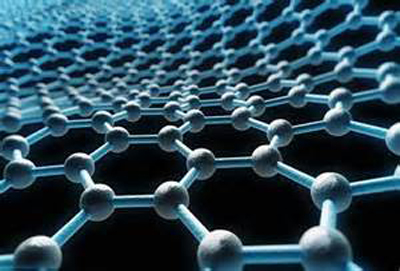

At present, the manufacturing process of graphene is very slow compared with more traditional electronic materials, which means higher costs. Now, researchers from University of Glasgow find that copper materials used in the manufacture of lithium-ion batteries can be quickly batch production of graphene. As a two-dimensional crystal of carbon atoms, graphene is the basic building materials of zero dimensional fullerenes, one dimensional carbon nanotubes and three dimensional graphite. These carbon nanomaterials have been used in the manufacture of all kinds of electronic products from solar cells to light bulbs and ultrasensitive gas sensor. But the production of large area high quality graphene, needs much higher production cost than silicon.

A large portion of the production cost is the substrate in the production of graphene. By using chemical vapor deposition (CVD) method, platinum, nickel or titanium exposed to ethylene and benzene in high temperature environment, produce a single layer graphene. Recent production method has lowered these costs, and the cost of this approach by adding copper as a substrate, is still expensive.

To help significantly reduce the cost, researchers use cheap copper foil usually in the manufacture of ultra-thin cathode (negative electrode) of lithium ion batteries, and deposit high quality graphen on its surface. Facts have proven that this kind of cheap copper foil is a good base material. The copper surface is completely smooth, very suitable for the formation of graphene, which costs $1 per square meter, and the previous expensive method costs $115 per square metre.

The research team believes that large-scale and low-cost synthetic method can realize the graphene based flexible photoelectric system, including bending display of mobile phones, electronic paper, high quality graphene film label with radio frequency identification (RFID), medical channel to provide drugs or monitor vital signs, electronic skin for robots and artificial limbs, etc.