The breakthrough claimed by the Technology Institute for Superhard and Novel Carbon Materials (TISNCM) in conjunction with the Siberian Federal University, is diamond substrate MEMS resonators whose speed exceeds 20GHz

The Russians are harnessing the piezoelectric effect on diamond substrates for microelectromechanical systems (MEMS) semiconductors. Claiming a new world's record in the microwave regime, their faster-than-silicon piezoelectric "acoustic wave" resonators have been successfully modelled for super-sensitive sensors, according to the Moscow Institute of Physics and Technology (MIPT).

The breakthrough claimed by the Technology Institute for Superhard and Novel Carbon Materials (TISNCM) in conjunction with the Siberian Federal University, is diamond substrate MEMS resonators whose speed exceeds 20GHz while maintaining a quality factor (Q) over 2,000. Such performance could be used not only just to produce high-speed clocking signals, but to create ultra-sensitive surface- and bulk-acoustic (SAW/BAW) wave resonators for biosensors that could detect near single bacteria and other nanoscale-quantities of toxic agents.

"High frequency SAW/BAW resonators have been studied by several authors. Several reports included relatively high frequencies (but less than 10GHz) and the quality factor was relatively low," researcher Arseniy Telichko from TISNCM told EE Times. "Our diamond-based device can operate at dozens of GHz by adjusting all its parameters, such as thickness, width and electrode material, and could result in near-single bacterium detection."

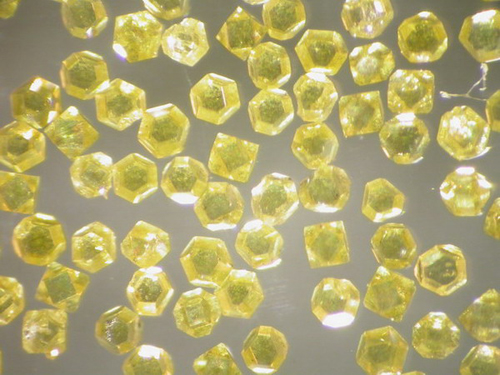

The Russians claim to be working on devices that outperform other researchers by virtue of fine-tuning of their high pressure high temperature (HPHT) deposition process. The other researchers referenced used slow-growth CVD processes, whereas the TISNCM chains its method is not only faster, but results in a more perfect crystalline lattice.

"The main point is that other authors usually use CVD diamond created with technology using relatively slow carbon deposition. The diamond crystal 'grows' slowly, forming a thin film. But such CVD growth makes the diamond very stressed with numerous internal forces 'unbalanced' in such crystals," Telichko told EE Times. "We, on the other hand, have used almost pure carbon synthetic single crystal diamond grown with HPHT. As a result, our diamond is in fact a single crystal, with minimum internal stress in the structure. So, our devices, based on single-crystal diamond operate at higher frequencies, have higher quality factor and are just better than CVD diamonds in general."

The trick to realising superior applications using its pure crystalline substrates, according to Telichko, is to layer piezoelectric material atop the substrates sandwiched between two metals (aluminium and molybdenum). As a result, the more resonant structures not only make possible higher frequencies, but also simultaneously realise higher Qs.

"The studied high-overtone bulk acoustic resonator is a structure where all the parameters are mainly determined by the substrate material. Using HPHT diamond instead of quartz, langatate, or even CVD diamond makes the device better with higher quality factors, higher operating frequencies (up to 20GHz) and less internal losses," Telichko told EE Times. "Recently we have shown that attenuation in diamond has linear frequency dependence after 1GHz, while all other crystals have squared dependence. That means, that attenuation energy losses after 1GHz increase slowly compared with other crystals, which makes diamond a perfect substrate for high-frequency electronic applications."

Previously in the lab, MIPT had experimentally studied and built a number of diamond-based resonators and shown them operating at >20GHz, "which is a world record for such devices," said Telichko. However, at such speeds Telichko's team had noticed some spurious peaks near the main overtone, resulting in the current work which explains and classifies them the result of Lamb-mode waves whose motion lies in the plane of the surface- and bulk-waves.

To maximise performance, the Russians are proposing a revised evaluation of the Lamb waves propagation. Using finite-element analysis, the propagation of the acoustic waves in the layered piezoelectric structure was studied in detail, and the dispersive curves of their phase velocity plotted.

For the future, the team plans to take the advantage of a promising new aluminium-scan-dium-nitrogen piezoelectric film, which may turn out to quell the Lamb-wave induced spurious peaks.