Industry 4.0/Industrial Internet of Things (IIoT) connectivity technologies to dominate 2017 show.

Hannover, Germany – Rollomatic S.A., based in Le Landeron, Switzerland, is one of the companies setting a course for an interconnected future for machinery. Precision is still a top priority, but monitoring machinery and production processes from anywhere in the world are growing more important.

September 18-23, 2017, manufacturers and technology companies will meet in Hannover, Germany, at the EMO Hannover 2017 trade show to see the latest innovations, including Internet-assisted tool-grinding.

Connectivity will allow manufacturers call up the status of a grinding machine while it is in operation, making sure that it is running smoothly from any computer connected to the Internet or company network.

Rollomatic plans to demonstrate key innovations, showing how easy it is to set up communication between the Rollomatic RMonitor and RConnect systems. RMonitor is monitoring software that can be used to check the efficiency of production. The system visualizes the status and historical performance of machinery and reports any needed preventative maintenance steps.

RConnect software links to an enterprise resource planning (ERP) system, i.e. via OPC, and offers the opportunity to analyze production statistics and plan processes.

Other Rollomatic products to be displayed in Hannover include:

LaserSmart 501

Aluminum and lightweight materials such as carbon-reinforced-plastic and titanium alloys are part of everyday business in the aviation and automotive industries. Tools fitted with PCD, CVD, or CBN, and increasingly those with monobloc designs, are especially suited to withstand the abrasiveness of fiber-reinforced plastics and the difficulty of machining tempered steel and other extremely temperature-resistant materials. The LaserSmart 501 can machine PCD/CVD/CBN tools, supporting extremely sharp and clearly defined cutting edges.

Damien Wunderlin, head of marketing and sales at Rollomatic SA, says, “In the past, key features of a PCD tool, such as its circular land chip breaker edges, had to be produced on separate machinery after eroding. The new LaserSmart 501 completes the entire process in a single clamp.”

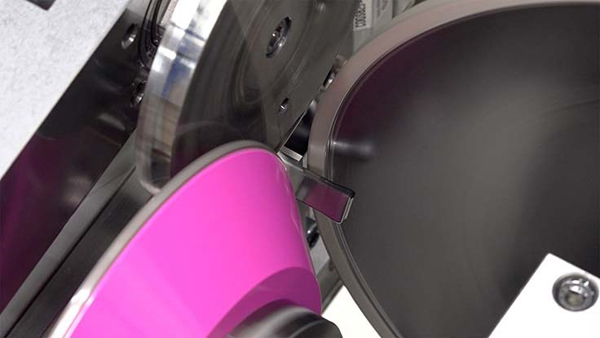

GrindSmart 629XS, 629XW

Six-axis grinding machines enable grinding wheels to be inclined during grinding, allowing for even larger relief angles and complex tool geometries to be ground. For spherical milling-cutters or partial radii , the sixth axis enables the grinding point to remain constant during the relieving operation and offers better surface finish and more accurate geometric precision.

“We have integrated a self-centering system into the grinding machines, which goes about its work entirely without any adjustment by the operator. Another new development is the addition of extra wheel packs in the wheel changer for the GrindSmart 629XW,” Wunderlin says.

Rollomatic grinding machines come with integrated measuring equipment that provides important data on the success of a grinding process via 3D probing of the tool. Contactless measurement, done without operator intervention, make it possible to compensate for anomalies triggered by sudden temperature fluctuations or incipient grinding wheel wear. Elliptical is the new round If a perfectly round circumference is a major quality feature of shaft-mounted tools, the situation is often somewhat different in the case of stamping and forming tools. “Requests from our customers have shown that demand for elliptical and non-round tools, for example, is growing. That’s why we have integrated the newly patent pending process in the 5-axis.

ShapeSmart NP5 pinch and peel grinding machine

The 5-axis machine design, coupled with SmartPunch technology, can grind non-round punches, threading tools, and stamping and forming tools with complex shapes.