The 3rd generation semiconductor material featured silicon carbide is rising rapidly thanks to its superior performance and have been widely used in photoelectric devices, power electronic devices.

The first-generation semiconductor silicon carbide materials aroused the rapid development of the information technology industry. Meanwhile, silicon carbide facilitated the formation of the high-tech industry cluster - "silicon valley". World semiconductor giants, such as Intel, were born. Actually, more than 95% of the semiconductor devices and over 99% of integrated circuits are made of silicon carbide materials.

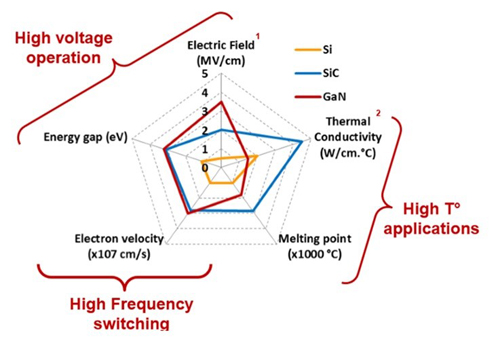

Currently, 40% of global energies are used as electric energy, the conversion of which consumes semiconductor devices. Silicon carbide power device can no longer meet the new social demand for high frequency, high temperature, high power, high energy efficiency, and resistance to adverse environment. The 3rd generation semiconductor material featured silicon carbide is rising rapidly thanks to its superior performance and have been widely used in photoelectric devices, power electronic device.

As a kind of wide-band-gap semiconductor material, silicon carbide has various advantages, such as favorable heat stability, high thermal conductivity, etc. Sic can be used to produce all types of heat-resistant and high-power devices.

LED semiconductor illumination is a breakthrough. Sic has solved the match degree problem between substrate materials crystal lattice and GaN. Higher power conversion efficiency and less heat radiation. Based on the principle, 303 lm/W LED lab luminous efficiency was born.

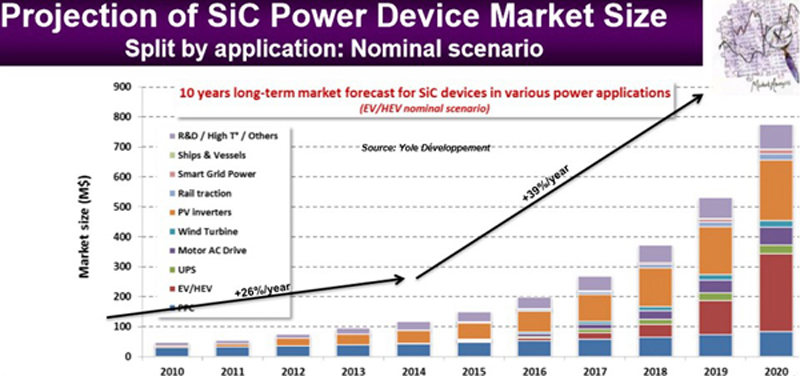

Sic semiconductor is gradually replacing Si semiconductor with reduced costs. It is predicted that Sic will drive an industrial revolution.

1. Sic materials are used in high-speed railway and can save over 20% energy.

2. Sic materials are used in new energy automobiles field and can save over 20% energy consumption.

3. Sic materials are used in household appliance field and can save 50% energy consumption.

4. Sic materials are used in wind power generation and can save over 20% energy.

5. Sic materials are used in solar energy field and can diminish photovoltaic conversion by 25%.

6. Sic materials are used in industrial motor field and can save 30% to 50% energy.

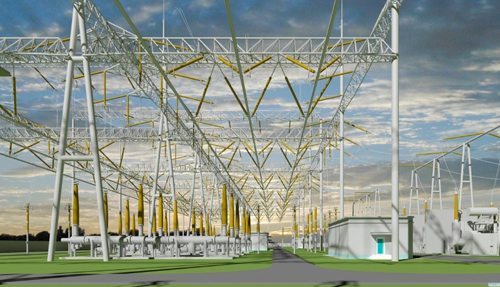

7. Sic materials are used in ultrahigh pressure DC electricity transfer and smart grid and can save electricity loss by 60%.

8. Sic materials are used in big data field and help data center reduce energy consumption. Currently, 3,000,000 sets of data centers consume 30,000,000 kWh.

9. Sic materials are used in communication sector and can improve signal transmission efficiency, safety and stability.

10. Sic materials are used in aerospace field and can reduce equipment consumption by 30% to 50%.

At the beginning of 2014, U.S. president Obama founded the 3rd Generation Wide-band-gap Semiconductor Industrial Alliance represented by Sic. According to statistics, the project has received $140,000,000 support from the U.S. federal government and local government.

In the near future, power device made of semiconductor Sic materials will become a trend of energy-saving technology. Semiconductor Sic power device is recognized as the "CPU" of power converter and the "key" of green economy.

Source: http://www.idacn.org/.