A team of Researchers from California, USA, have now produced a new self-assembly growth approach to produce cubic-BN nanodots using plasma-assisted molecular beam epitaxy (MBE).

Out of the many boron nitride (BN) structural forms, cubic boron nitride (c-BN) nanodots (NDs) offer the potential for a variety of new opportunities across a plethora of applications. Until now, experimental attempts have only been possible under extreme high-temperature and/or high-pressure conditions, and generally result in an impure product with a mixture of phases.

A team of Researchers from California, USA, have now produced a new self-assembly growth approach to produce cubic-BN nanodots using plasma-assisted molecular beam epitaxy (MBE).

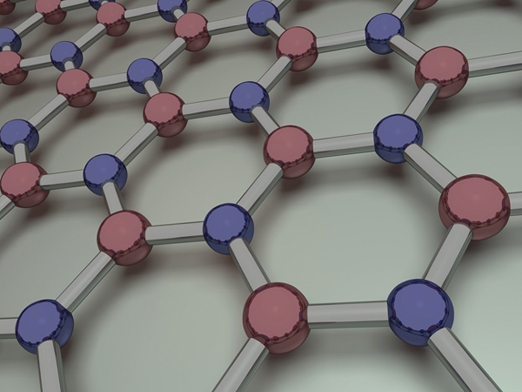

Boron nitride is a group III-IV compound which showcases an isoelectronic structure, similar to that of a carbon lattice. Boron nitride’s ability to adopt both sp2 and sp3-bonded phases allows it to adopt a variety of structures, including hexagonal (h-BN), rhombohedral (r-BN), turbostratic (t-BN), cubic (c-BN) and wurtzite (w-BN) boron nitride.

Currently, cubic boron nitride nanodots have the potential for many applications, including in batteries, biology, deep ultraviolet light emitting diodes, sensors, filters and other optoelectronic applications.

Therefore, to be feasible on a commercial level, the synthetic process needs to be optimized to both remove the impurities and produce a single structured material. This has now been realized by these US-based Researchers.

The team used plasma assisted molecular beam epitaxy (MBE), in a high vacuum environment, to grow cubic boron nitride nanodots onto cobalt and nickel substrates using a self-assembly approach. The result was a simple fabrication process that offered a product with a great degree of quality, purity and reproducibility.

The self-assembled growth of nanodots an important nanofabrication process. It allows the building blocks to spontaneously organize themselves into random and/or ordered distributions by thermodynamic and other constraints.

To characterize the cubic boron nitride nanodot samples, the Researchers used a combination of Raman Spectroscopy (HORIBA LabRam), scanning electron microscopy (SEM, XL30-FEG), atomic force microscopy (AFM, Veeco AFM D3100), X-ray photoelectron spectroscopy (XPS, Kratos AXIS ULTRA), X-ray diffraction (XRD, Philips, PW1730) and transmission electron microscopy (TEM, FEI/Philips CM-30). The cubic structure was realized through XRD, XPS and Raman spectroscopy, whereas SEM and AFM were used to realize the time evolution growth.

The nucleation, formation and morphological properties of the cubic boron nitride nanodots were closely correlated with the nature of the substrate, be it from the catalysis effect, lattice-mismatch-induced strain, roughness and the growth conditions, in particular, the growth time and growth temperature.

The mean lateral size of the nanodots on the cobalt substrate (the better substrate) ranged from 175 nm to 77 nm, depending on the growth time. The growth mechanism of cubic boron nitride nanodots on the metal substrates was concluded to arise from the Volmer-Weber (VW) mode. The density was also found to be in the order of 109 cm-2.

The growth mode was to be responsible for the formation of the cubic boron nitride nanodots, where the elastic strain was found to be the dominating factor for the determination of the total energy of formation on metal substrates.

The mechanism of formation was found to produce a chain-like arrangement of nanodots on the surface. The Researchers have attributed this to the concave surfaces located with the substrate materials. These concaves act as a preferential nucleation site for cubic boron nitride nanodots, which leads to a chain-like alignment of nanodots along the valleys. It was found to be the opposite for convex substrates.

The self-assembly process enables a high-quality nanoscale product to be produced. Conventional methods, that utilize high temperatures and pressures, are not able to produce a product on this scale, and as such this research paves the way to realize cubic boron nitride nanodots as contenders for commercial implementation into catalysis, battery, biology, deep ultraviolet sensor and optoelectronic technologies.