Ceramic grinding wheels produced by Noritake Co. in Nagoya, usually used to cut or grind metal and glass, are gaining unexpected attention thanks to the increasing popularity of Japanese food in other countries.

Ceramic grinding wheels produced by Noritake Co. in Nagoya, usually used to cut or grind metal and glass, are gaining unexpected attention thanks to the increasing popularity of Japanese food in other countries.

Demand for grinding wheels is expected to expand at home and abroad as more companies use them to grind soybeans to make tofu.

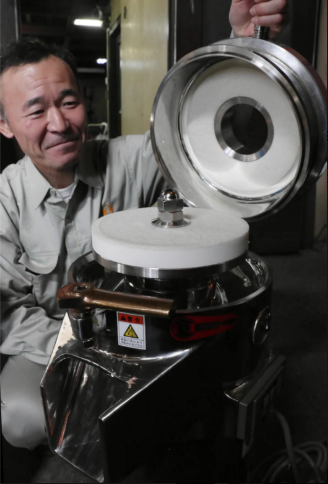

Nagasawa Kikai Seisakusho Co., based in Kawaguchi, Saitama Prefecture, is a major maker of soybean grinding machines used to produce namago, a fluid substance made of crushed soybeans and water.

In July, the company received an order for 20 new machines from a tofu manufacturer in Beijing.

The company produces roughly 200 machines annually, of which 10 percent were exported to Asia and Europe in recent years. This year, exports are set to break into the 20 percent range, the firm said.

A bean grinding machine has two disk-shaped grinding wheels, one placed on top of the other to rotate and mash soybeans poured in between.

According to Otofu Kobo Ishikawa, a large tofu maker in Takahama, Aichi Prefecture, the softness that makes Japanese tofu special is attributable to the homogeneity of the grind, which is difficult to achieve without using ceramic grinding wheels.

“As manufacturers of Japanese-style tofu increase abroad, I believe the demand for bean grinding machines using grinding wheels will also increase,” said Noburu Ishikawa, 53, the firm’s president.

For a long time, stone mills were used to mash soybeans, but around 1958, Nagasawa Kikai Seisakusho decided to use ceramic grinding wheels made by Noritake that are stronger than stone, and combined them with a motor to build a new product.

As a result, the company was able to reduce the time it takes to grind the soybeans to less than 10 percent of what it took by stone, sparking a revolutionary shift to mass production for a food that has been made for over 1,000 years.

Currently, almost all domestically made bean grinding machines use the ceramic wheels made by Noritake.

Noritake started out as a manufacturer of Western-style plates, but it shifted its focus to grinding wheels as part of its contribution to the munitions industry during the war.

The company quickly grew into the leading grinding wheel manufacturer in Japan, with half of its ¥100 billion in sales stemming from related businesses.

Although grinding wheels for food account for less than 1 percent of Noritake’s sales, Asahi Shuzo Sake Brewing Co., which produces Kubota, the popular sake brand in Nagaoka, Niigata Prefecture, has been using Noritake’s grinding wheels to polish rice for 30 years.

Asahi Shuzo says it is essential to use polished rice with consistent quality to assure the vital subtlety of taste in sake.

The grinding machines are also used by chocolate manufacturing companies to grind cacao beans.

The disks have minute ceramic grains on the surface with diameters ranging from 0.001 mm to 3 mm, depending on the purpose. They can be used for a wide variety of tasks ranging from cutting steel pipe to sharpening the tips of injection needles.

Noritake began producing grinding wheels in 1907 to finish porcelain ware and started manufacturing the wheels for industrial use in 1939.

The company’s wheels are now widely used in the production of anything from automobiles and aircraft to medical equipment and semiconductors.