This article talks about the introduction and application of diamond saw blade and its great suppliers at iAbrasive.

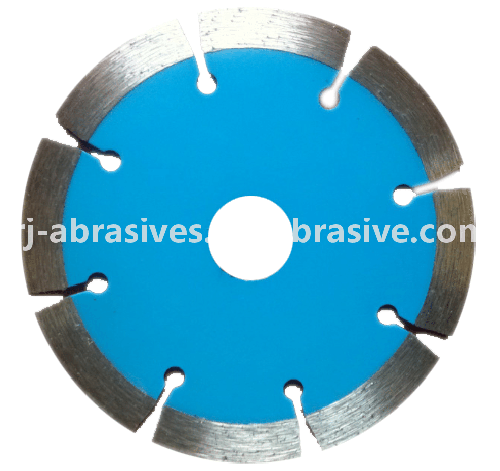

Diamond saw blade is a kind of cutting tool, which is widely used the processing in concrete, refractory materials, stone materials, ceramics and other hard brittle materials. And diamond saw blade is available in different shapes, such as circular diamond saw blade, diamond band saw blade and diamond gang saw blade, which has extensive applications for marble, granite, concrete, asphalt, masonry, and gem-cutting blades.

With the rapid development of automobile, aviation and space technology, higher requirements on the properties and the processing technologies of materials are brought up. New materials are widely used in the industry, such as carbon fiber reinforced plastic, particle reinforced metal matrix composites (PRMMC) and ceramic materials. The material has high strength, good abrasion resistance, and small thermal expansion coefficient, which shorten the life of the cutting tool machining on them. Developing new type of wear-resisting and stable superhard cutting tool is the subject of many universities, research institutes and enterprise. Diamond has many excellent performance of mechanics, optics, thermology, acoustics and optics. In addition, it has high hardness, low friction coefficient, high thermal conductivity, low thermal expansion coefficient and chemical inertness, which is an ideal material to manufacture cutting tools.

The application of diamond saw blade:

A. The processing of non-ferrous metal materials

When processing copper, zinc, aluminum and other non-ferrous metals and their alloys, these materials are easy to adhere to cutting tools, which makes the processing difficult. Making full use of the low friction coefficient, low affinity with non-ferrous metal of diamond, it can effectively prevent the bonding between metal with knives. In addition, because of the large diamond modulus of elasticity, when the cutting, it has little deformation and also little deformation on the cutting non-ferrous metal extrusion, which can complete cutting process under small deformation, and thus can improve the machining surface quality.

B. The processing of non-metallic materials

A large amount of high hardness particle non-metallic materials that is hard to process, such as glass fiber reinforced plastic, hard carbon fiber/epoxy resin composite material, its hard spot makes the blade wear serious, and carbide blades are difficult to process. Therefore, diamond blade with high hardness and good wear resistance, has high machining efficiency.

C. The ultra precision processing

With the advent of modern integration technology, the machining develops in the direction of high precision, and it puts forward very high requirements on the performance of diamond blade. Because of the small friction coefficient, low thermal expansion coefficient, high thermal conductivity of diamond, and very thin scrap, the scrap is easy to flow but not easy to react with other substances. In addition, it has low calorific value and high thermal conductivity, which can avoid the influence of the heat on the blade and workpieces. Therefore, the blade is not easy to passivate and the cutting deformation is small so that high quality surface can be obtained.

Here some great suppliers that can offer high quality diamond saw blade for you. You can visit their website by clicking here: Yuzhou Hehui Superabrasives Co.,ltd, Beijing Xin Bai Bentley Superhard Materials Co., Ltd., EEMO Ceramic Materials Co.,Ltd., and Henan He Hui Abrasives & Tools. They are popular suppliers at iAbrasive.

If you would like to learn more about diamond saw blade and other abrasives, please feel free to visit iAbrasive.com-a B2B web portal located in Zhengzhou, China, which is devoted to the development of abrasives foreign trade B2B platform. Here you will meet more buyers and great suppliers to help you get better deals.

At iAbrasive, our mission is to create a good platform for chatting and interaction, expanding buyers and suppliers interaction space and interactive way, and bring our customers more business opportunities and exceptional value. Click on the link www.iabrasive.com to get more business opportunities, or click on the “register” link if you are interested in becoming a member of iAbrasive.