This article mainly introduces the installation and usage of grinding wheel.

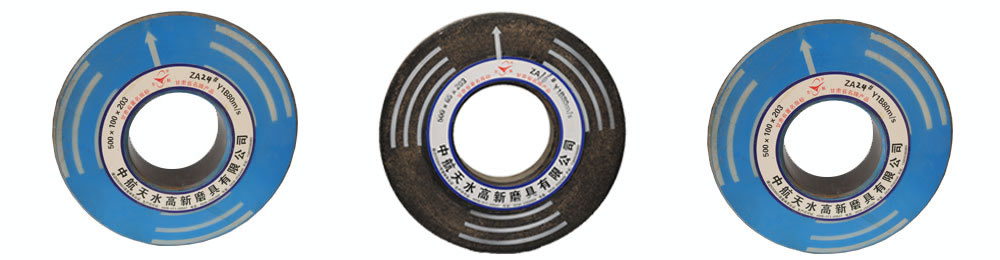

Grinding wheel, also called bonded abrasives, is made by bonding ordinary abrasive into a certain shape (mostly circular with central hole), with a certain intensity of consolidation. It generally consists of abrasives, binder and porosity, and the three parts are called three elements of bonded abrasives. According to different classification of binder, it is commonly divided into ceramic (bond) grinding wheel, resin grinding wheel (bond) and rubber wheel (bond). Dosage of grinding wheel in abrasives tool is the largest and it is also the most widely used for various grinding, cutting and machining operations.

Installation and Usage of Grinding Wheel:

A. The grinding wheel appearance inspection must be conducted before installation and usage, to check if there is a crack or damage; use wooden hammer to knock grinding wheel, and the sound should be clear; Before using, it should be made turning test according to standard GB/T2493 provisions, otherwise, it is strictly prohibited.

B. Before installation the machine tool spindle speed should must be checked, which should not exceed the maximum operating speed of grinding wheel's mark.

C. The fastening grinding wheel only allows the use of special nut wrench, and it must be symmetrically on opposite sides of the spindle in sequence and gradually be tightened. In total, the nut elastic should be appropriate. It is prohibited to use complementary fixture or tapping tool.

D. Turn off the cooling fluid in order to avoid the grinding wheel unbalance.

E. The aperture and the grinding wheel spindle and the matching between the chuck should comply with the regulations of GB4674 standard.

F. The newly installed wheel must be in the case of a shield, work in idle speed in the following time:

Outer diameter <400 mm diameter of the grinding wheel is not less than 2 minutes, a diameter of 400 mm or grinding wheel is not less than 5 minutes. When idling, the operator cann’t stand in front of the grinding wheel or its tangent direction.

G. Some not specifically for grinding wheel (such as parallel wheel), shall not use grinding wheel face for grinding; and not external cylindrical grinding wheel is not allowed to use cylindrical grinding wheel for grinding (such as cup wheel), in order to avoid the grinding wheel to be broken.

H. When grinding workpiece, it is forbidden to use leverage to push workpiece to increase the pressure of the grinding wheel.

I. For wafer grinding wheel and the cymbals wheel, when cutting, too much strength is prone to stalling stuck and bump and cause the damage of grinding wheel. When cutting the work piece cutting, please cut them one by one in case of accident.

If you need high quality grinding wheel or would like to learn about other abrasives, please feel free to visit iAbrasive.com-a B2B web portal located in Zhengzhou, China, which is devoted to the development of abrasives foreign trade B2B platform. We have offered many chances for buyers and suppliers for better deals. For example, some grinding wheel suppliers are very popular gold members at iAbrasive and if you are interested, you can visit AVIC Tianshui New & High Abrasives Co., Ltd., ZHEGNZHOU BOSDI ABRASIVES CO.,LTD., NANTONG HUIXIN GLASS FIBER CO.,LTD., Henan Yuxin Abrasives Co., Ltd., EEMO Ceramic Materials Co.,Ltd., Henan He Hui Abrasives & Tools., etc.

At iAbrasive, our mission is to create a good platform for chatting and interaction, expanding buyers and suppliers interaction space and interactive way, and bring our customers more business opportunities and exceptional value. Click on the link www.iabrasive.com to get more business opportunities, or click on the “register” link if you are interested in becoming a member of iAbrasive.