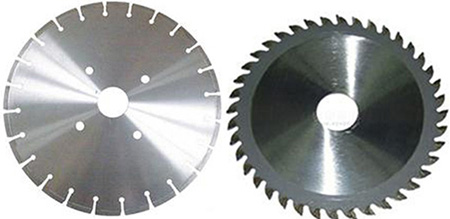

Diamond thin circular saw blade playes a large role in the production of stone materials, which not only saves the cost, but also improves the work efficiency.

Diamond thin circular saw blade playes a large role in the production of stone materials, which not only saves the cost, but also improves the work efficiency. Regarding how to use diamond thin circular saw blade, we will talk about several opinions.

First, the sharpness of diamond segment is the first key.

Because of thinner thickness of thin saw blade, its rigid also weakens from mechanics point of view. In order to make it keep the original standard thickness of cutting performance, the sharpness of diamond segment is the first key, in addition to the rigidity, hardness and others reaching a certain standard. Improving the sharpness of diamond segment is decided by the following five factors:

A, To improve the strength of diamond, and the diamond must have higher strength than standard segment;

B, To increase the proportion of diamond coarse mesh, namely the proportion needs to be increased above 60% in the 40/50 #;

C, To reduce the concentration of diamond, usually under 25%;

D, To choose reasonable matrix formula, namely the low temperature metal binder formula;

E, To shorten the length of thesegment, shorning from 24mm to 21mm.

Second, it can reduce the input power.

Because of thinner matrix, its rigid also weakens, and the tolerance (torsion) of saw blade is also reduced accordingly; the segment has strengthened its sharpness, so the cutting force increases, and the cutting resistance decreases. Therefore, most of main motors adopt the original 30kw that now can be changed to 22kw, and the yield can reach the original standard.

Three, it can avoid the influence of thermal stress.

Thin circular saw blade should try to adopt low temperature type silver welding in the process of welding segment. The heating time should be short, preventing larger heat affected zone; During welding, it’d better use interval welding and take turns to weld after a week.

Four, current limiting (overload) protection is impirtant.

Please install the current limiting controller to control the current of the motor. When the current of the motor has more than you need, it will control the motor rising in 0.5 seconds, and when rising to the current that you need, it will automatically stop rising, so that it can automatically protect the diamond thin circular saw blade, and make the service life of the thin circular saw blade doubled.